Solutions in Water Environment

for People and Planet

Hi, I'm looking for the last Vol.1 Secondary Battery Wastewater IssuesWe'd like to follow up on our initial interest in the secondary battery and water industry trends.

In the previous article, I said that instead of blaming companies for overly enforcing environmental protection, it is better to wait and watch with common governance with the government.

그 사이 한국환경공단은 ‘민관합동 기술지원반’을 개설 해 기업을 도우고 있으며, 대기업들은 폐수 처리에 대한 신기술을 내놓아 회수에 촛점을 두고 있습니다.

If any problems arise, environmental technology is solved by trial and error of technology development and application.

We will continue to monitor the performance of domestic companies and the government's governance of the secondary battery industry.

Vol. 2 may seem a bit far removed from the water industry and dewatering and wastewater, but if you read on, you'll see why lithium is relevant to the water industry.

In Vol. 3, we will discuss the use of decanter centrifuges for mine refining, which is applied to secondary batteries, the zero-discharge system used to recycle waste batteries, and the Decantercentrifuge, We introduce the processes used to generate salt wastewater and the companies in Korea.

But first, a quick global overview of the secondary battery industry.

Secondary batteries are currently in a bit of a lull in the electric vehicle industry, for a variety of political reasons that are complicated by international law.

There are many reasons for this, including US subsidies and lithium mining rights, US sanctions on China, wartime energy issues, the rekindling of the gray hydrogen-blue hydrogen-green hydrogen debate, environmental concerns about lithium brine, and the technical maturity of recycling technologies.

There is also an opposition between the ternary batteries NCM (LNCMO - lithium cobalt oxide + nickel + manganese) and LFP (Li- FePO4 - lithium iron phosphate).

NCM with Ni, the main material in battery cathode materials, has the advantage of higher energy density with a higher percentage of Ni and longer range per charge, but has a higher unit cost than LFP.

LFPs, on the other hand, do not use the expensive cobalt that NCMs use, so they have a lower cost of production, higher stability, and Olivine's hexahedral structure.

Therefore, many companies are struggling with technology development over whether to use NCM or LFP because they have an industrial structure where everything from mining to refining and distribution of lithium can be set at the lowest cost.

Currently, Tesla, the iconic electric car brand, has adopted LFP, which is cheap, reliable, and low in fire risk, but has a range disadvantage.

‘안전’이라는 측면에서 아무래도 자동차 생산 기업들이 선호하는 배터리는 LFP로 갈려서 테슬라의 배터리 생산업체인 CATL(45GWh)과 BYD(10GWh)가 내년 생산 목표 물량 55GWh을 모두 LFP로 한 것입니다.

On the other hand, the three major Korean battery companies that dominate NCM are also looking to make changes.

This is because not only Tesla, but also Toyota and Volkswagen are LFPs and are at a crossroads in the global movement.

Recognizing this, LG Chem is building an LFP anode plant in Morocco and has set a target of 50,000 tons per year by 2026. POSCO FutureM has established a plan to produce 20,000 tons of LFP anodes in 2025 and 150,000 tons in 2030.

Meanwhile, Sungil High Tech, a company known for recycling secondary batteries, is researching and developing a technology that recovers all lithium, phosphate, and iron, given the difficulty of recycling existing LFPs, and aims to commercialize it in 2026 through a pilot test in 2024.

이처럼 두 기술의 양강체제에서 기업들은 환경문제의 공통 고민을 가지고 ‘재활용’의 가장 큰 걸림돌문제를 해결하려는 움직임을 보이고 있는 실정입니다.

The differences between the two technologies are outlined below, and it's largely a matter of the three Korean companies versus China.

| Separation | Lithium iron phosphate (LFP) | NCM (Nickel, Cobalt, Manganese) |

| Fire hazard | Low | Normal |

| Mileage | Short | Long |

| Lifetime | Long | Normal |

| Pricing | Low | High |

| Energy Density | Low | High |

| Producer | China CATL, BYD | LG, SK, Samsung (some models have introduced LFP lineup) |

| Pros | Inexpensive, low development difficulty | Short charge time and limited range |

| Cons | Heavy and weak output | Lower reliability than LFP and higher production unit costs |

| Buffer | Up to 70% | Up to90% |

| Unit price per 1 kWh | 50$ | 63$ |

| Cycle lifetime | Thousands of times | Short-lived |

| Recycled/Recyclable | Unavailable or Low | Depending on skill level, 95% or more can be recovered. Buy 300K, sell 1000K, recycle like new. |

American John Goodenough, who was awarded the Nobel Prize in Chemistry in 2019 at the age of 97, was instrumental in developing the current battery scheme.

Sadly, Dr. Goodenough passed away in June of this year at the age of 100, but the battery concept he developed, coupled with the practicality of recycling technology, is making great strides toward EV batteries.

John Goodenough spent 24 years developing random access memory for computers and batteries, and is considered the father of modern magnetic theory.

Humanity was gifted with a technological revolution in lightweight and powerful energy storage, paving the way for modern portable electronics like laptops and cell phones.

Since then, Goodenough's team at the University of Texas has also been involved in the development of batteries made of glass, and as the global EV market has opened up, manufacturers have been faced with the choice between NCM and LFP.

Secondary batteries are included in the four major industries of semiconductors, displays, secondary batteries, and bio as a milestone for the Korean government, which will provide policy financing of 14.7 trillion won next year.

The secondary battery is the Cheongju-Pohang-Ulsan-Saemangeum Secondary Battery Specialized Complex, and 39.2 billion won will be provided to the complex next year.

The automotive sector, which includes rechargeable batteries, will be supported by an increase of 101 TP3T in the budget from 32.26 billion to 354.9 billion this year, and the R&D of rechargeable batteries will increase by 13.41 TP3T from 46.3 billion to 52.5 billion.

As shown above, the local government has recognized that secondary batteries are the high-tech industry of the future and has increased investment in specialized complexes and R&D budgets, while LG has announced its vision to build a global production hub by investing KRW 15.1 trillion by 2030, and SK Energy has decided to invest KRW 1.5 trillion to build a domestic battery market.

In addition to the public wastewater pipelines in Pohang and Saemangeum Industrial Complex, the Ministry of Environment established a joint public-private operation team to help tenants with unfamiliar administrative and technical issues in wastewater treatment.

국립환경과학원·한국환경공단의 산하기관과 민간 전문가로 구성된 이 ‘민관 합동 기술지원반’은 입주기업의 폐수처리를 도와 지역주민과 국민이 안심할 수 있도록 하고 있습니다.

NCM과 LFP는 이처럼 기업과 정부가 공통으로 기술개발과 환경영향적 평가에 맞는 수처리 분야의 기술개발도 같이 진행 돼 ‘극복과제’를 인식하며 규제에 걸 맞는 폐수 배출 기준을 마련하는 환경정책과의 동반성장을 이루며 발전하게 되는 첨단 산업 분야입니다.

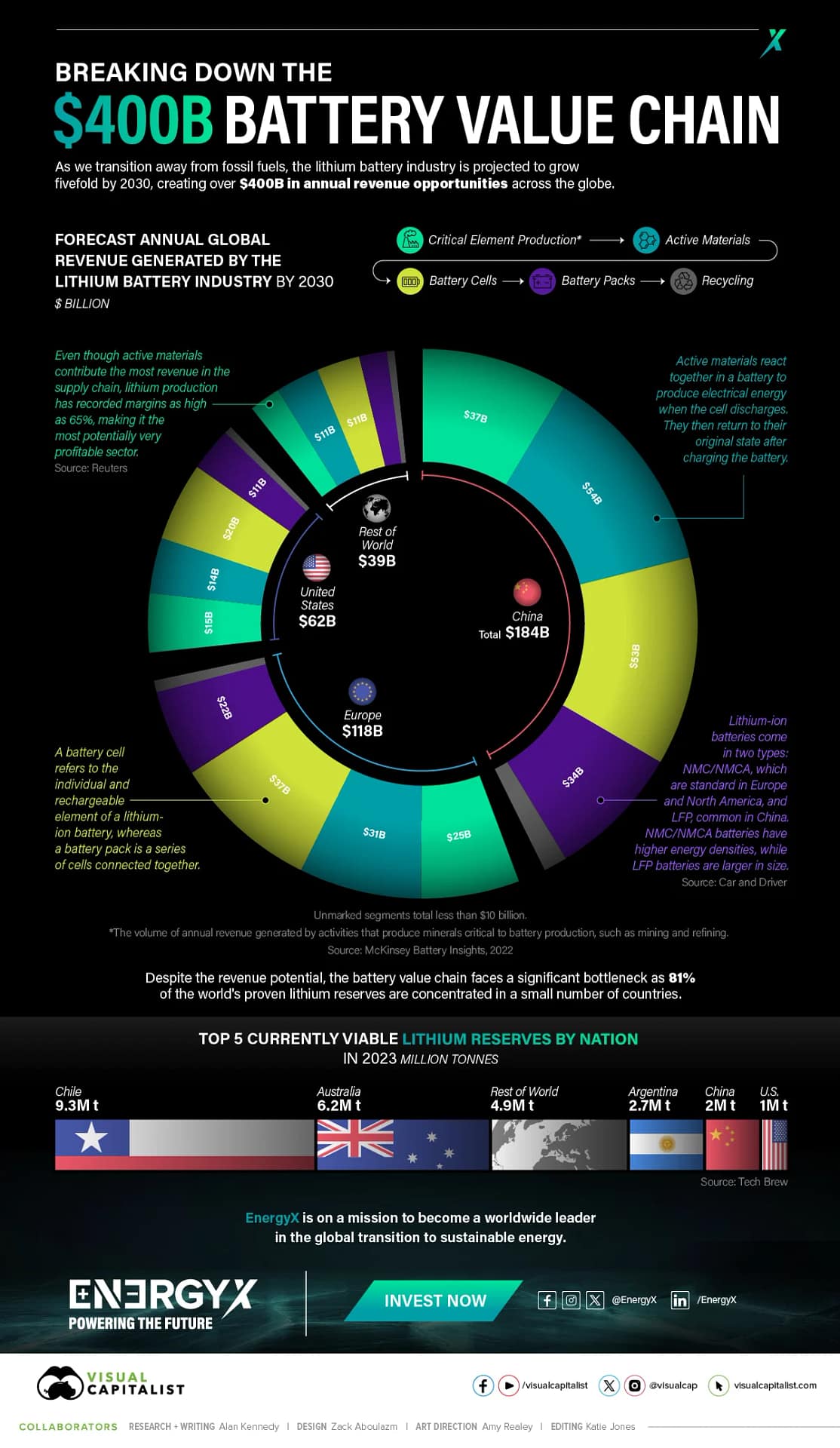

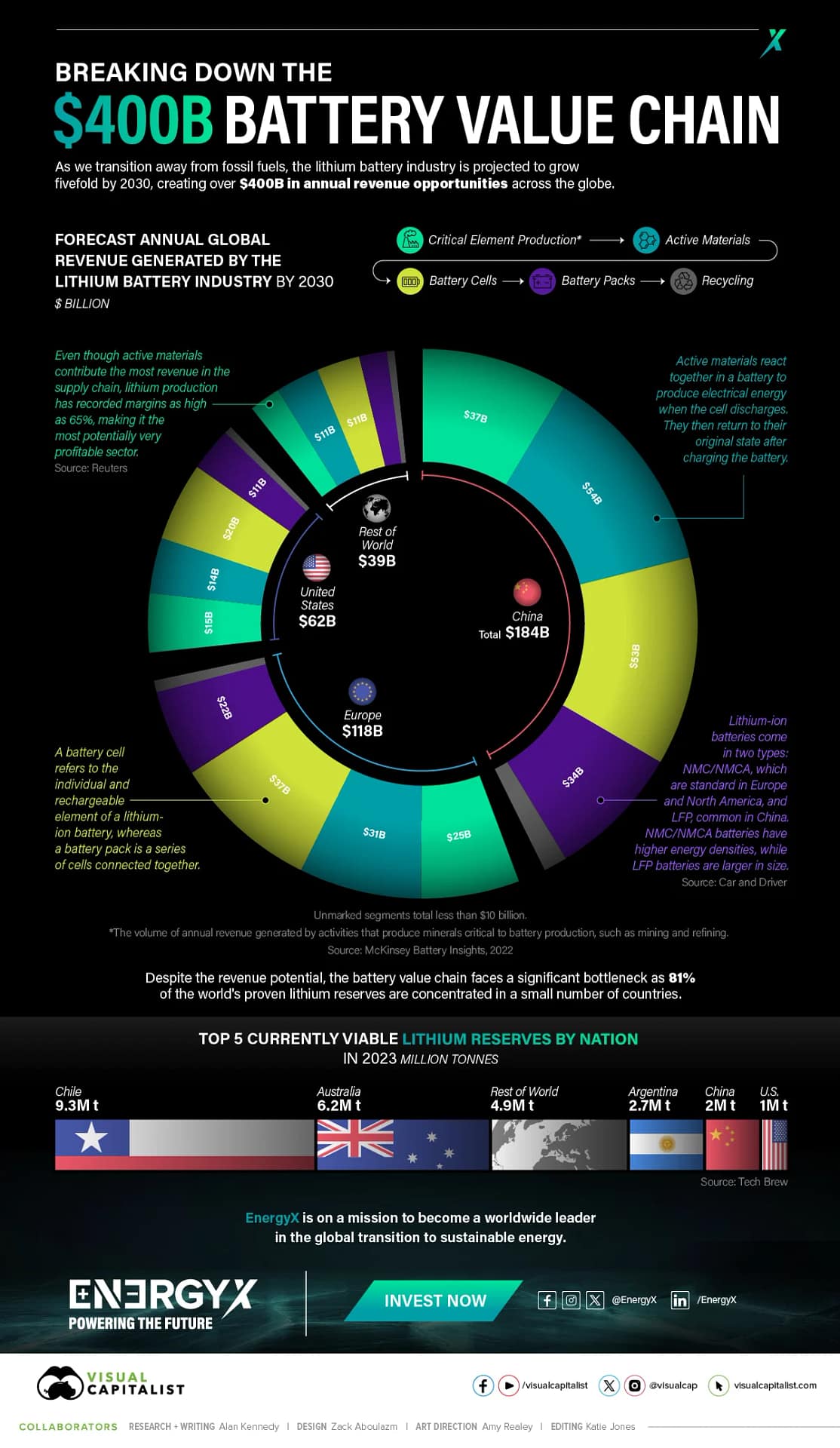

Source: https://www.visualcapitalist.com/sp/lithium-battery-value-chain/

The main source of lithium for secondary batteries is Australia and South America, as shown above. It is important to note that lithium is a finite resource, so battery manufacturers around the world are still searching for new mines through geographical exploration.

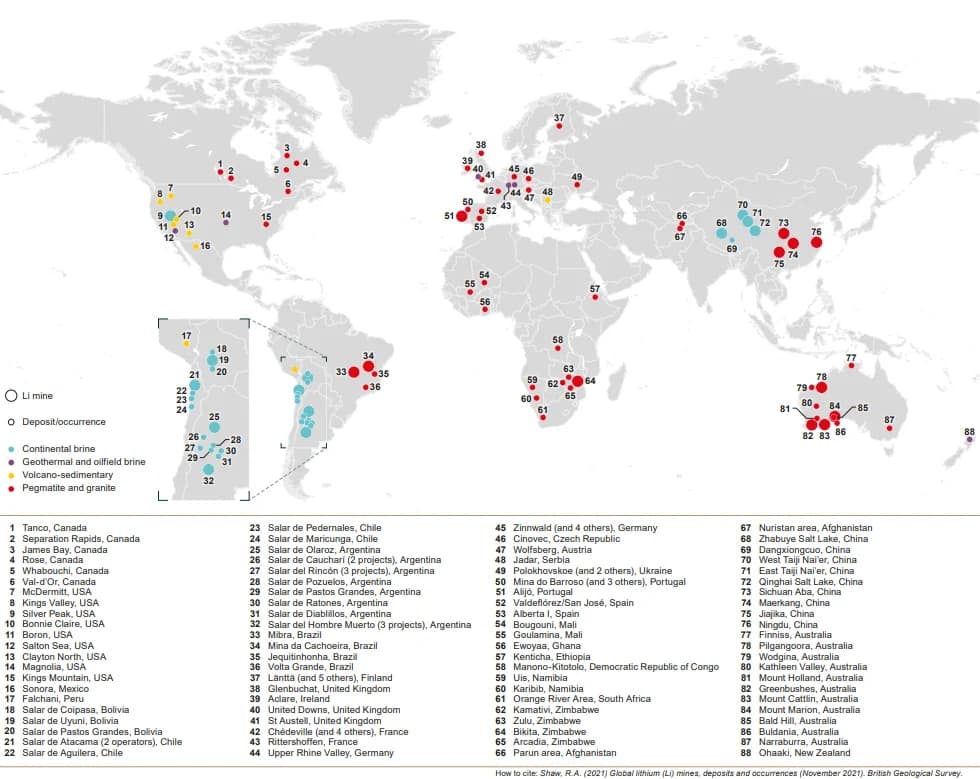

A map of lithium mines worldwide as of 2021 is shown below.

Global Lithium Resource Map | Source: https://www2.bgs.ac.uk/

Lithium, the primary material for full-scale secondary batteries, is mined and refined in a variety of ways.

Battery companies are already making inroads in South America with lithium mining, with major production occurring in the salt lakes of Chile, Peru, and Argentina. In addition, the world's largest high-concentration lithium mine has been discovered in Nevada, USA.

However, at the same time, it requires a huge amount of local groundwater, which means that up to 2 million tons of water is used to obtain one ton of lithium, causing friction with local indigenous people and the loss of biodiversity.

실제로, 남미에선 정부가 리튬채굴기업을 고발하는 사례가 이어지고 있으며 멕시코의 경우 ‘리튬국유화법’을 내걸어 리튬 쟁탈전을 의식하고 있습니다.

출처 : 전기차 핵심광물 리튬, ‘친환경 산업’의 이면 (KBS_318회_2023.07.15.방송)

Currently, extraction is accomplished through one of two main methods: mining and surface brine extraction.

Mining the ore is an expensive and time-consuming process, requiring exploration and geological surveys before extraction can begin. The lithium can then be separated using a centrifuge, which involves applying large amounts of heat (over 1000 degrees) to change the spodumene into β-spodumene, which is then cooled. Since fossil fuels are used, the process has been criticized in environmental impact assessments for its high carbon dioxide generation and many byproducts.

This is the method used in the United States, China, and Australia, and is primarily practiced in Australia.

This is the predominant method practiced in Bolivia-Argentina-Chile, known as the Lithium Triangle, which produced 331 TP3T of the world's supply as of 2021.

Extraction by natural drying using sunlight is less geologically and environmentally intensive, but brine extraction requires vast amounts of water. Lithium brine is pumped to surface pools, mixed with chemicals, evaporated, and the separated and concentrated lithium salts are collected and processed into usable materials.

In brine evaporation, the chemical precipitation process is the primary method for recovering lithium from brine extraction. It is relatively simple and inexpensive and requires pH adjustment. The solubility of lithium ions is reduced by using ions of opposite propensity and the solid precipitate is separated by filtration or precipitation. The process of evaporating water and adding sodium carbonate to obtain lithium carbonate has the limitation that it is water-insoluble, which is too water-intensive to concentrate from brine until the lithium content exceeds 0.51 TP3T.

The main disadvantage of the most popular brine evaporation method is the 12-18 month drying period, which results in slow lithium production and high groundwater consumption.

Welchron Hantec, a medium-sized Korean company, provides equipment to POSCO, and unlike conventional salt evaporation, the process can be completed in as little as 8 hours to 1 month.

The high purity (>99.91 TP3T) and extraction rate (>801 TP3T, up from 30-401 TP3T) allows for the parallel production of not only lithium but also the value-added product lithium hydroxide-potassium hydroxide.

Welchron Hantec is a construction company that has transformed into an environmental company as mentioned in the last column, and at the same time, it is a mid-sized company that leads various facilities related to secondary batteries, zero discharge, and lithium production, and is listed on the KOSDAQ as a technology leader in the market.

For nickel, another material for secondary batteries, WelchronHantec has a nickel sulfate concentration and crystallization facility.

For nickel, unlike lithium mentioned earlier, the main producer is Indonesia, not South America or Australia.

To obtain high purity nickel sulfate, it is necessary to produce good quality crystals without impurities, and the existing refining facility (batch type) has the inefficiency of crystallizing aqueous solution > centrifugation and drying repeatedly > > starting and stopping the facility.

Welchron Hantec's nickel sulfate concentrate crystal facility is a continuous process with low process losses, which improves energy use.

Chemical Engineering Journal a study published in the Journal of the American Chemical Society, proposed a scalable spiral microstructure electrochemical reactor (SMER) to achieve lithium extraction in low-grade brine conditions. The method proposes a way to overcome previous lithium extraction challenges in low-grade brine technologies and offers a new way to scale up sustainably and commercially.

The study showed that the SMER operated at 5.6 times the lithium extraction rate of current state-of-the-art devices.

A new method has extracted lithium from Lake Taijinar. It is more difficult to mine than most lithium resources due to its low lithium concentration and high magnesium to lithium ratio.

The solar-powered SMER operated stably at a Li extraction rate of 21.96 mg g-1 h-1. The researchers suggested that the method could be effectively scaled up to produce lithium hydroxide for batteries commercially.

The efficiency of the brine evaporation method is highly dependent on the presence of other ions and impurities that can co-precipitate and complicate the extraction process. For example, magnesium has similar ionic properties to lithium and both have similar radii.

Producing high-purity lithium from brines with high Mg/Li ratios is a significant technical challenge for scientists and engineers working in the lithium extraction industry.

One of the most commonly used industrial extraction methods is carbonate precipitation, but this method requires relatively high concentrations of lithium to work properly.

Carbonate precipitation is not suitable for newly discovered brine sources with low lithium concentrations, so better methods must be developed if brine evaporation is to become a future-proof method of lithium extraction.

Declining flamingo populations in Chile's Atacama Desert salt lakes | Source: VOX

Lithium is found naturally as a dissolved mineral in brine aquifers, clay deposits, igneous rocks, and seawater. The main economic sources of lithium are rocks and brines, with brines accounting for about 601 TP3T of global production.

Mainly, Bolivia (21 million tons), Argentina (19 million tons), and Chile (980 tons), with the world's largest mine recently discovered in the US state of Nevada.

Among other environmental concerns, lithium mining requires two million liters of water to mine one ton of lithium, depleting local groundwater. This has led to a shortage of drinking water for indigenous people and a decline in the population of species living in desert lakes and salt lakes.

There are several environmental issues associated with lithium extraction and utilization. Mining harms the environment, and brine evaporation requires vast amounts of water and chemicals to separate the valuable lithium metal from the liquid.

게다가 리튬은 유한한 천연자원이라, 남미 리튬3국 – 볼리비아,아르헨티나,칠레의 매장량이 모두 고갈된다면 새로운 대체지를 찾아야 하고 또 같은 문제가 발생하게 되겠죠?

Due to the environmental, technical, and socioeconomic challenges of current lithium extraction methods, it is important for scientists, industry, and government organizations around the world to find alternative methods.

Land use change, resource bottlenecks, and even fossil fuel emissions are hindering the green potential of lithium extraction, so whether NCM or LFP, alternative technologies must be developed under the assumption that resources are finite.

Habitat destruction from mining and pollution leads to biodiversity loss. This affects local food chains and the security of vulnerable populations who rely on the local environment for food and economic income.

Chemical contamination of local aquifers and rivers has serious implications for future generations of indigenous people.

Addressing these environmental issues and technical challenges is essential to ensure the sustainability of lithium extraction and related technologies, and consequently, ensuring that lithium extraction methods are as environmentally friendly as possible is an important mission of our generation's green revolution.

As demand for lithium grows and awareness of the environmental impact of extraction methods increases, many scientists and companies are developing new technologies.

For example, Lilac Solutions is developing an innovative modular ion exchange method that improves extraction efficiency and reduces environmental damage and water use.

EnergyX, meanwhile, is offering direct lithium extraction using metal-organic skeleton nanoparticles.

In other research, ion exchange resins are emerging as a viable alternative to current methods, and scientists in Germany and the UK have investigated the feasibility of extracting lithium from lithium-rich granite in geothermal energy plants.

More recently, new precipitation methods have also been studied. Researchers have explored the use of sodium phosphate salts to improve lithium recovery, which is essential for extracting resources from dwindling deposits.

Other studies have used phosphoric acid to recover lithium from alkaline leach solutions.

However, while promising, some major challenges remain. For example, aluminate precipitation has emerged as a suitable method in brines with high Mg/Li concentrations, but it is expensive and consumes a lot of alkaline compounds. More research is needed to refine new advances in lithium extraction.

1. refining/ smelting of spodumene ore

The mining of spodumene ore in Australia is the most common method of mining spodumene ore, which is a disadvantage because the ore uses fossil fuels in the smelting process. The separation process uses centrifuges.

2. salt lake evaporation method :

-The Lithium Triangle in South America (Bolivia, Argentina, and Chile), where water is added to a salt lake and evaporated. It is an environmentally friendly method, but it is also criticized for its difficulty in reusing water, as water consumption can reach 2 million liters per ton of lithium.

3. smer:

-Other methods suggested in the literature, etc.

In Korea, NCM is the main type, China prefers LFP, and most automakers prefer LFP. This is because the risk of fire is low, so as a developer, there is less risk of liability in the event of an accident.

However, LFP is on the rise globally, and domestic developers are all increasing their LFP lineup and development, and recycling technologies that were previously impossible are being tried.

Spodumene ore extraction requires the use of fossil fuels, and salt lake evaporation uses large amounts of water, which can deplete local groundwater.

Vol.1 Saemangeum Secondary Battery Wastewater Information Insight Vol.1 : View

Vol.2 What is Secondary Battery Brine Wastewater? ARK Environment : View

Vol.3 Lithium Mining and Environmental Impact Assessment - Secondary Battery Insightsvol.3 : View

Vol.4 Zero Liquid Discharge (ZLD) and Secondary Battery Wastewater - Background, Pros and Cons : View

Vol.5 List of domestic companies related to secondary battery wastewater treatment : View