Solutions in Water Environment

for People and Planet

This is the last installment of our series on secondary battery wastewater, and we will discuss the treatment process and domestic companies.

Basically, in the previous article, we discussed the problems with secondary battery wastewater.

Secondary battery technology is an ongoing development, so naturally, wastewater treatment is also being developed with various attempts. Today, we will introduce the processes and domestic companies that are good for basic salt wastewater treatment.

ZLD stands for zero discharge system, which is a technology that is currently at the high end of the water treatment market, like ultrapure water.

‘아예 방류하지 않겠다’라는 취지를 전제로 하는 기술로 이는 곧 ‘물 재이용을 하겠다’라는 결론을 품고 있는 기술입니다. 하지만, ZLD는 열에너지 사용이 워낙 많고 이산화탄소 배출이 많은 기술입니다.

The ideal picture would be a more advanced ZLD approach that reduces thermal energy use and leads to zero emissions.

In my last column, I mentioned that the law of conservation of energy dictates that discharging fresh water into the ocean without reusing it will cumulatively cause the entire earth's groundwater to flow into the ocean, distorting the earth's rotation axis and resulting in groundwater depletion > water migration, as in the case of Indonesia.

The purpose of ZLD is to achieve multiple benefits. The idea is to reuse all of the water rather than waste it, leaving only the pollutants behind.

‘염폐수’의 무서운 점은 염이 생태독성을 일으키며 TU수치로 이를 파악하는 것은 민물보다 바다가 훨씬 어렵기 때문입니다. 또한, 신체 영향도에 따른 연구도 많이 미흡합니다.

For secondary batteries, cobalt is harvested in some African countries where children are often used as laborers, and for lithium, there is a lack of in-depth research on the health effects.

염은 생태계와 생명에게 미지의 알 수 없는 위험이 따르기에 염폐수에 대해 가장 이상적인 시스템은 ‘ZERO LIQUID’의 ZLD무방류 시스템입니다.

Reference : Chulhwan Moon, "Zero Discharge System Policy and Technology, Future Directions", KOSEN Analysis Report

ZLDs were applied in the 1970s to regulate high concentrations of flue gas desulfurization wastewater and cooling tower discharges from offshore power plants in the United States.

As the number of power plants increased and the salinity of the nearby sea increased, the number of ZLDs continued to increase, reaching 60/82 as of 2008.

The largest users of ZLD are power plants > electronics > fertilizers > chemical plants > mines.

The U.S. recently amended its legislation to prioritize ZLDs for wastewater discharges from flooring and fly ash conveyances and flue gas mercury removal systems.

China uses fossil fuels to produce chemical raw materials and has applied ZLD primarily in coal mines. This is because most mines are located in areas with few freshwater sources, making water reuse essential.

In countries like the United States, most power plants are equipped with ZLDs, with the largest proportion of ZLDs being installed in coal>chemical plants, with ZLDs ranging from 110 to 2,300㎥.

Textile factories that discharge more than 25 cubic meters of wastewater per day have been required to install ZLDs since 2015. As of 2008, 29 dyeing plants were equipped with ZLDs to reuse water and recover and use separated salt.

In addition to textile mills, brewing, alcohol distillation, power plants, and petrochemical plants are identified as potential markets for ZLD.

기본적인 ZLD의 기술은 ‘열이용 연속공정의 증발기술’을 사용해 왔습니다.

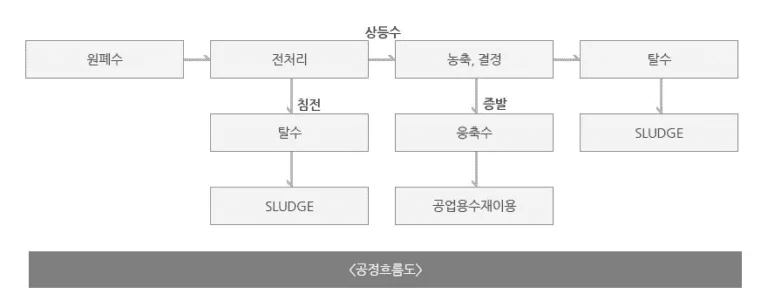

The approximate process of the ZLD system is shown below. It can be roughly categorized into two stages: pre-treatment and post-treatment of concentrate.

Pretreatment (descaling of ions) > Raw water (demineralized concentrate) > Brine concentrator (MVC) > Brine crystallize or evaporation ponds

Source:Making Waves; Zero liquid discharge for sustainable industrial effluent management, Water (2021), 13, 2852. https://doi.org/10.3390/w1320285

Because ZLDs use so much energy, reducing the amount of wastewater entering the crystallizer is necessary to reduce operating costs, and because they produce so many greenhouse gas emissions, a variety of technologies are being used in parallel with ZLDs to reduce these emissions.

| Technical name | Pros | Limiting factors | Energy consumption |

| RO Reverse osmosis | Low energy use High technology maturity Modularized | Low processable salt concentration (up to 70,000 mg/L) Membrane fouling | Seawater: 2 to 6 kWh/m3 produced water Radix: 1.5 to 2.5 kWh/m3 produced water |

| ED/EDR Electrodialysis | High processable salt concentration (up to 100,000 ppm) Even if the concentration of silica is high, the membrane Fewer salts Modularized | Highly salty wastewater It takes a lot of energy to process. What it takes and how much it costs If the treatment of non-charged contaminants is Difficulty | 7-15 kWh/㎥ raw water (Circles with salt concentrations above 15,000 mg/L number) |

| FO Isosmosis | High processable salt concentration (up to 200,000 ppm) Low-temperature heat sources are also available Modularized | Low permeability even at high salt Contaminant Migration in Induced Solutions Possible contamination of treated water due to Lack of field use cases | 21 kWh/㎥ raw water (The salt concentration of the raw water is 73,000 mg/L, For a recovery rate of 64%) |

| MD Separators | High processable salt concentration (up to 200,000 ppm) Low-temperature heat sources are also available Less membrane fouling Modularized | Low permeability and recovery Poor treated water quality when wetting the separator If volatile contaminants are present, after Requires genus processing Lack of field use cases | 40-45 kWh/m3 produced water 22 to 67 kWh/m3 produced water |

| MVC Salinity Concentrator | High technology maturity High processable salt concentration (up to 200,000 ppm) | Requires large amounts of energy High setup and operational costs Operating at high temperatures Not modularized | 20-25 kWh/m3 raw water 28-39 kWh/m3 raw water |

Source : Zero Discharge System Policy and Technology, Future Directions | Chulhwan Moon (Trends Report) https://kosen.kr/info/kosen/REPORT_0000000001061

Source: https://www.doosanenerbility.com/heavy_file/business/data/water_epc/Water_plants_10th_Edition_kr.pdf

Doosan Heavy Industries & Construction had a variety of seawater desalination technologies based on its ability to build the world's largest desalination plant in the Middle East. As explained above, ZLD is possible only with sufficient experience and infrastructure in RO technology, so Doosan had the technology to order large quantities of ZLD.

Generally, zero-discharge treatment facilities are based on reverse osmosis (RO) or evaporation technologies and are deployed in conjunction with various wastewater treatment processes such as softening, biological treatment, MF/UF, and others, depending on the characteristics and conditions of the wastewater at the source.

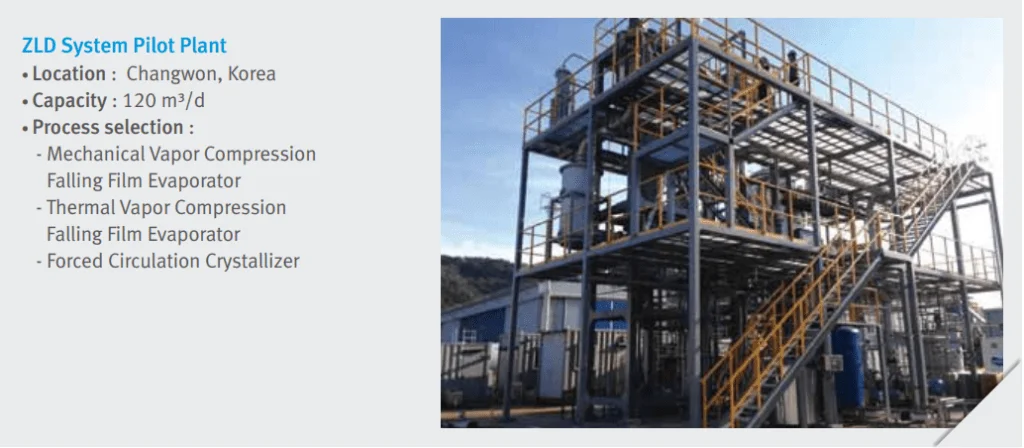

As the world's largest seawater desalination supplier, Doosan Heavy Industries & Construction's know-how in evaporation technologies such as multi-stage evaporation (MSF) and multi-effect (MED), as well as reverse osmosis processes, has enabled it to develop a zero-discharge treatment facility (120m3/d), and is in the process of expanding its capacity to more than 4,000 m³/d. In addition, the company is undertaking a zero-discharge treatment facility project at a petrochemical facility in Saudi Arabia, the first of its kind in Korea.

Source: WelchronHantech official website : http://www.hantec.co.kr/html/energy05.asp

Welchron Hantech is a company with a variety of technologies related to secondary batteries.

Lithium extraction facilities (Concentrated Crystal Facility), recycling facilities, separation membrane facilities, and wastewater treatment facilities.

We provide crystallizer facilities for mining lithium and nickel, which are raw materials for secondary batteries, recycling facilities for recycling resources, and finally wastewater treatment.

Source: KistEngineer Official Blog : https://blog.naver.com/dhsung73/223226796524

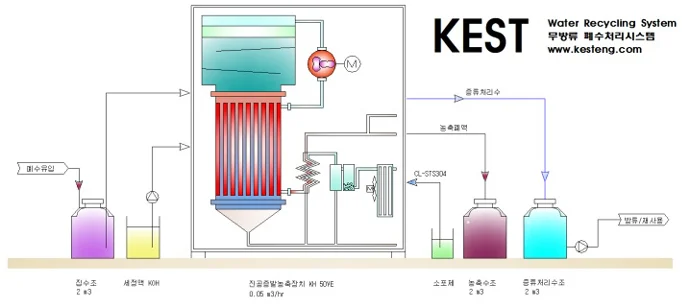

KistEngineer's KISTHYDROMAT Vacuum Evaporative Concentration SystemThe most outstanding feature of Less energy(6,000~10,000 won per ton).

The closed-system control of thermal energy ensures that no additional energy is required beyond the power required to operate the vacuum pump alone.

It is an energy circulation type system that boils and condenses wastewater by operating a vacuum pump without supplying a separate heat source (electric heater, gas, steam) and explains that it is an evaporative concentration system that reduces the cost of wastewater treatment and is inexpensive to operate.

The 90%'s clean water can be recovered and reused or discharged/non-discharged, describing the benefits below.

KistEngineer's NMP Solvent RegeneratorThe

The cost of the NMP (N-Methyl-2-Pyrrolidinone) solvent used in the preparation of the cathode active material in this lithium-ion production process is a significant contributor to production costs.

KistEngine's NMP solvent regenerator can be applied to the recovery process of NMP, helping to reduce the cost of the secondary battery process.

The pretreatment process is divided into flocculation, biological treatment, and sedimentation to remove the scaling of ions in brine wastewater, and the posttreatment process is the process of treating raw water/concentrated water, such as ultrafiltration, UF-RO reverse osmosis, and evaporative concentration. Various methods such as multistage reverse osmosis, forward osmosis, and electrodialysis can be used for post-treatment.

Doosan Heavy Industries & Construction has the largest ZLD plant order, Welchron Hantec has a ZLD for secondary batteries, and KistEngine is a domestic SME that services evaporative concentration equipment ZLDs.

Zero discharge systems are used to remove water from raw water through evaporation/crystallization and physically separate the remaining solids for landfill. Some of the materials from the brackish water may be landfilled or recycled, and the centrifuges are made of SUS316 and tungsten steel.

Vol.1 Saemangeum Secondary Battery Wastewater Information Insight Vol.1 : View

Vol.2 What is Secondary Battery Brine Wastewater? ARK Environment : View

Vol.3 Lithium Mining and Environmental Impact Assessment - Secondary Battery Insightsvol.3 : View

Vol.4 Zero Liquid Discharge (ZLD) and Secondary Battery Wastewater - Background, Pros and Cons : View

Vol.5 List of domestic companies related to secondary battery wastewater treatment : View