We provide a selection guide for screw press model selection by type, understanding, concentration, and application. ARK is a specialized company that develops and distributes one of the few multi-disc screw presses in Korea. As the only company with a local factory in Vietnam and the only domestic company that has expanded overseas with a focus on centrifugal dehydrators, we are also a pioneer in multi-disc screw presses and provide the best efficiency.

MLSS is the concentration of suspended solids in an abandoned tank during microbial treatment of sewage. The unit of MLSS is usually mg/L. MLSS is mainly composed of microorganisms and non-biodegradable suspended solids. MLSS is used as an important indicator of the water treatment process as a factor to indicate that there is a sufficient amount of active biomass (microorganisms) consuming organic matter. If the MLSS in the reactor is kept constant, the remaining sludge is called surplus sludge, and the amount of surplus sludge is the amount of dewatering that is desired.

Suspended solids are small particles suspended in water.

Total solids are the residue left after the water is evaporated by heating the sample to 105-110°C, also known as evaporated residue, which represents the total amount of solids, both suspended and dissolved solids combined.

Volatile solids are the organic components that volatilize when the total solids are heated, also known as heat loss. The VS content in the sludge is an important factor affecting the moisture content of the dehydrated cake.

DS is an abbreviation for Dried Solids. When selecting an ARK dehydrator, the unit of solids volume is based on dry solids. Dry solids are calculated as flow rate (㎥/hr) × concentration (ppm) = kgDS/hr.

A percent is a number or ratio expressed as a percentage of 100. Percent is often represented by its symbol, ‘%".

For example, 45% means 45/100 or 0.45.

ppm is a dimensionless unit that expresses small values such as parts per million or parts per mass. ppm is a pure number, independent of the units in which it is measured, and usually represents 10-6.

1% = 10,000 ppm = 10,000 mg/L, 0.8% = 8,000 ppm = 8,000 mg/L

The history of our municipal sewage treatment plants began more than 200 years ago in England, and the technology was transferred to Japan. Initially, sewage entered the treatment plant through sewer pipes in England and was treated with a process called activated sludge, which is a process in which oxygen is added to the aeration tank or reaction tank to break down organic matter through microorganisms under aerobic conditions.

The sludge treated by this process was relatively well settled, with concentrations of over 10,000 mg/L and 11 TP3T. These sludges were sufficiently dewatered by a system that adds polymer flocculants to the sludge and dewaters it. ARK is applying RT type for such sludge with good settling, and below [Figure] is a system of flocculation in flocculation-mixing tank and dehydration in dehydrator with ARK RT type.

[ Figure 2 ] ST-Type

In Europe, septic systems that separate sewage are not common due to low rainfall and sparse housing. However, in Japan and South Korea, the sewage collection system only collects sewage, resulting in high concentrations of sludge. Due to this high concentration, nitrification of sludge naturally occurs in the summer when the temperature is high, and a process to treat T-N through natural denitrification was introduced.

Since such treatment methods utilize light nitrate-producing microorganisms, the concentration of the sludge is reduced and lightened due to poor sedimentation, which makes it difficult to directly dewater the sludge, which is about 7,000 mg/L, 0.71 TP3T or less, and even 4,000 mg/L or less, making it difficult to directly dewater with conventional belt dewatering machines and centrifugal dewatering machines. To solve this problem, the method of placing the concentration facility in the front and dewatering after concentration has become a common phenomenon in Japanese and Korean sewage treatment plants.

ARK has developed a dehydrator that can concentrate and dehydrate such low-concentration sludge in a batch dehydration method without installing a separate concentration facility, and it is the ST system.

[ Figure ST Type ]

In addition, this ST-Type automates the dewatering system by dewatering surplus sludge at a low concentration of about 2,000 mg/L directly from the wastewater tank, and reduces installation costs by eliminating thickening tanks, retention ponds, and odor facilities.

[ Figure Conventional dehydration method ].

[Figure ST-Type Treatment Plant Application Example].

In conclusion, the ARK-RT system is recommended for sludge concentrations above 1.01 TP3T and the ARK-ST system for sludge concentrations below 11 TP3T.

An important factor in selecting a dehydrator is the amount of solids. The unit for solids is kg-DS/hr, where DS stands for Dried Solids.

The solids volume is calculated as the product of the flow rate and concentration of the incoming sludge, and the model selection can be selected in the following ways. RT-TYPE and ST-TYPE can be selected according to the concentration of incoming sludge, and dehydrator model can be selected according to the amount of solids.

As mentioned earlier, the RT-TYPE is appropriate for incoming sludge concentrations of 1.01 TP3T or more and the ST-TYPE is appropriate for concentrations of 11 TP3T or less.

The structure and principle of the RT-Type, which is suitable for relatively high concentration sludge, consists of a flocculation mixing tank and a dewatering system. Sludge enters the flocculation tank inlet through a pipe ([Figure 1]-①) from the sludge reservoir to the sludge transfer pump as shown in Figure 1.

Only a certain amount of the sludge transported to the flocculation tank inlet is sent to Part 2, and the remaining sludge is U-turned to the treatment plant through the piping ([Figure 1]-②).

In Part 2, the constant polymer transported through the piping ([Figure]-③) using the polymer pump as shown in [Figure 1] and the sludge introduced into the lower part of the flocculation tank ([Figure 1]-④) through Part 1 are stirred by the agitator installed in the upper part of the flocculation tank.

The sludge entering through the lower part of the flocculation mixing tank is then separated into flux and filtrate by the action of the polymer. After being separated into flux and filtrate, it enters the dehydration facility, i.e., the dehydrator, through the input pipe ([Figure 1]-⑤).

[ Figure 1 ] RT-Type

The ST-Type, which is suitable for low concentration sludge, consists of a thickening unit and a dewatering unit. The sludge is concentrated in the thickener and then sent to the dewatering unit.

As shown in the figure below, the sludge is piped from the sludge storage tank to the sludge transfer pump ([Figure 2]-①) to the bottom of the thickening plant.

The sludge entering the lower part of the thickening facility is moved by the lower impeller installed at the bottom, where the sludge and chemicals are mixed and gradually moved to the upper part, separated into flux and filtrate, and moved in a solid and large flux ([Figure 2]-②).

At the top of the concentrator, the upper impeller generates a pre-rotating current to grow a larger flux ([Figure 2]-[3]).

The filtrate outlet installed at the top of the center of the thickening plant excludes the filtrate separated into filtrate and flux through the filtrate outlet and enters the treatment plant ([Figure 2]-[4]), and the concentrated sludge is fed to the dewatering plant ([Figure 2]-[5]).

[ Figure 1 ] ST-Type

The method below is applicable for incoming sludge concentrations of 2.51 TP3T or less. For incoming sludge above 2.51 TP3T, the dehydrator model can be selected by referring to the separate table below.

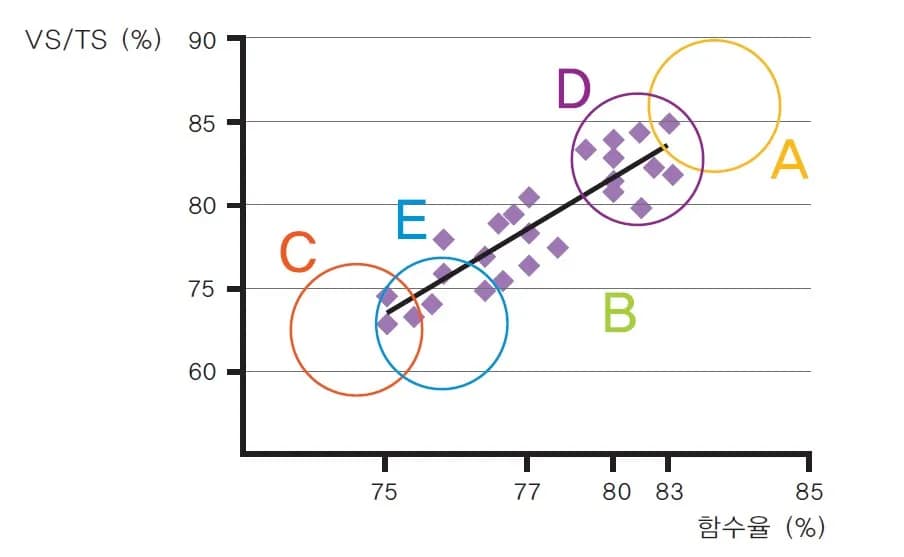

Since the dewatering capacity varies depending on the sludge characteristics, the sludge area corresponding to each treatment plant is selected according to the graph and description below.

[ Change in water content with VS/TS ].

The most important factor in model selection is solids volume. Solids volume is calculated as the product of flow rate and concentration, and is a function of the solids

The amount is used to select the appropriate model. The solids selection method is as follows.

Solids Volume (kg-DS/hr) = Flow Rate (m3/hr) × Concentration (mg/L)

Separation | RT-Type | ST-Type |

Design Conditions | 1. influent sludge concentration: 15,000 mg/L (1.5%) 2. inflow flow rate: 30 ㎥/day 3. dehydrator uptime: 8 hr/day | 1. influent sludge concentration: 8,000 mg/L (0.8%) 2. inlet flow rate: 20 ㎥/day 3. dehydrator uptime: 8 hr/day |

Design Calculations | 30 ㎥/day ÷ 8 hr/day × 15,000 mg/L = 56.25 kgDS/hr | 20 ㎥/day ÷ 8 hr/day × 8,000 mg/L = 20 kgDS/hr |

[ when flow rate, concentration is known ]

Design Conditions | 1. cake production : 5 ton/day = 5,000 kg/day 2. water content: 80 % |

Design Calculations | 5,000 kg/day ÷ 24 day/hr × 20/100 = 42 kgDS/hr |

Remarks | When the amount of cake and moisture content are known, select the solids amount, and select the ST-Type if the sludge generated is in Zone D or RT-Type otherwise.

D zone, select ST-Type, and select RT-Type in other cases. |

[ cake yield, water content ].

The processing capacity of the dehydrator varies depending on VS/TS and moisture content. Therefore, the solids volume obtained in 3-2-3 is applied to the organic content (VS/TS) by sludge area (A, B, C, D) and the processing capacity of each model according to the target moisture content to select a model.

(If it doesn't match the solids volume listed in the throughput by target moisture content, you can select a TYPE with a higher throughput than the solids volume.)

TYPE | Maximum throughput by target function rate (kgDS/hr) | |||||

60% | 65% | 70% | 75% | 80% | 85% | |

101 | Due to the nature of sludge, it is difficult to guarantee moisture content. | 6 | 8 | |||

102 | 12 | 16 | ||||

201 | 10 | 13 | ||||

202 | 20 | 26 | ||||

203 | 30 | 39 | ||||

204 | 40 | 52 | ||||

401 | 35 | 40 | ||||

402 | 70 | 80 | ||||

403 | 105 | 120 | ||||

601 | 80 | 100 | ||||

602 | 160 | 200 | ||||

[ Table A-1 ]

TYPE | Maximum throughput by target function rate (kgDS/hr) | |||||

60% | 65% | 70% | 75% | 80% | 85% | |

101 | Due to the nature of sludge, it is difficult to guarantee moisture content. | 6 | 8 | 10 | ||

102 | 12 | 16 | 20 | |||

201 | 10 | 13 | 15 | |||

202 | 20 | 26 | 30 | |||

203 | 30 | 39 | 45 | |||

204 | 40 | 52 | 60 | |||

401 | 35 | 40 | 47 | |||

402 | 70 | 80 | 94 | |||

403 | 105 | 120 | 141 | |||

601 | 80 | 100 | 120 | |||

602 | 160 | 200 | 240 | |||

[ Table B-1 ]

TYPE | Maximum throughput by target function rate (kgDS/hr) | |||||

60% | 65% | 70% | 75% | 80% | 85% | |

101 | Due to the nature of sludge, it is difficult to guarantee moisture content. | 6 | 7 | 9 | ||

102 | 12 | 14 | 18 | |||

201 | 10 | 12 | 14 | |||

202 | 20 | 24 | 28 | |||

203 | 30 | 36 | 42 | |||

204 | 40 | 48 | 56 | |||

401 | 35 | 38 | 42 | |||

402 | 70 | 76 | 84 | |||

403 | 105 | 114 | 126 | |||

601 | 80 | 90 | 105 | |||

602 | 160 | 180 | 210 | |||

[ Table B-2 ]

TYPE | Maximum throughput by target function rate (kgDS/hr) | |||||

55% | 60% | 67% | 73% | 75% | 80% | |

101 | Due to the nature of sludge, it is difficult to guarantee moisture content. | 6 | 8 | 10 | ||

102 | 12 | 16 | 20 | |||

201 | 10 | 14 | 17 | |||

202 | 20 | 28 | 34 | |||

203 | 30 | 42 | 51 | |||

204 | 40 | 56 | 68 | |||

401 | 35 | 45 | 50 | |||

402 | 70 | 90 | 100 | |||

403 | 105 | 135 | 150 | |||

601 | 80 | 120 | 140 | |||

602 | 160 | 240 | 280 | |||

[ Table C-1 ]

RT type is selected when the incoming sludge concentration is 2.5% or more depending on the flow rate concentration as shown below. However, in the case of high concentration, if it is calculated by solids volume, the model is selected by referring to the C area, and if it is selected by predicting the flow rate alone, it is selected by referring to the table below.

Separation | RT-Type |

Design Conditions | 1. influent sludge concentration: 25,000 mg/L (2.5%) 2. inlet flow rate: 20 ㎥/day 3. dehydrator uptime: 8 hr/day |

Design Calculations | 20 ㎥/day ÷8 hr/day ×25,000 mg/L = 62.5 kgDS/hr |

[ when flow rate, concentration is known ]

TYPE | Maximum throughput by target function rate (kgDS/hr) | |||||

60% | 65% | 70% | 75% | 80% | 85% | |

101 | Due to the nature of sludge, it is difficult to guarantee moisture content. | 0.25 | 0.3 | 0.35 | ||

102 | 0.5 | 0.6 | 0.7 | |||

201 | 0.5 | 0.6 | 0.7 | |||

202 | 1 | 1.2 | 1.4 | |||

203 | 1.5 | 1.8 | 2.1 | |||

204 | 2 | 2.4 | 2.8 | |||

401 | 2.6 | 3 | 3.5 | |||

402 | 5.2 | 6 | 7 | |||

403 | 7.5 | 9 | 11 | |||

601 | 5 | 6 | 8 | |||

602 | 10 | 12 | 1 | |||

[ Table D-1 ]

⊙ A-zone (VS/TS 85% or higher, when target function rate is 80%)

[Refer to Table A-1 and select the type that corresponds to a solids volume of 56.25 kgDS/hr.

TYPE | Maximum throughput by target function rate (kgDS/hr) | |||||

60% | 65% | 70% | 75% | 80% | 85% | |

101 | Due to the nature of sludge, it is difficult to guarantee moisture content. | 6 | 8 | |||

102 | 12 | 16 | ||||

201 | 10 | 13 | ||||

202 | 20 | 26 | ||||

203 | 30 | 39 | ||||

204 | 40 | 52 | ||||

401 | 35 | 40 | ||||

402 | 70 | 80 | ||||

403 | 105 | 120 | ||||

601 | 80 | 100 | ||||

602 | 160 | 200 | ||||

[ Table A-1 ]

Since the solids volume is 56.25kgDS/hr, the appropriate type is 402 as shown in the table above.(Selecting a product with a throughput that exceeds the solids volume) When selecting the RT-402 type, if the target moisture content is kept at 85%, the solids throughput increases to 80kgDS/hr, but the cake generation increases due to the high moisture content.

⊙ B-zone (VS/TS 80%, when target function rate is 80%)

[Select the type that corresponds to a solids volume of 56.25 kgDS/hr from Table B-3.

TYPE | Maximum throughput by target function rate (kgDS/hr) | |||||

60% | 65% | 70% | 75% | 80% | 85% | |

101 | Due to the nature of sludge, it is difficult to guarantee moisture content. | 6 | 7 | 9 | ||

102 | 12 | 14 | 18 | |||

201 | 10 | 12 | 15 | |||

202 | 20 | 24 | 30 | |||

203 | 30 | 36 | 45 | |||

204 | 40 | 48 | 60 | |||

401 | 35 | 38 | 42 | |||

402 | 70 | 76 | 84 | |||

403 | 105 | 114 | 126 | |||

601 | 80 | 100 | 120 | |||

602 | 160 | 200 | 240 | |||

[ Table B-3 ]

Since the solids volume is 56.25kgDS/hr, the appropriate type is 402 as shown in the table above.

When selecting the RT-402 type, maintaining a target water content of 851 TP3T will result in a solids throughput of 84 kgDS/hr.

However, it increases the amount of cake produced due to the high water content.

⊙ C region (VS/TS 60% or less, target function rate 75%)

[Refer to Table C-1 and select the type that corresponds to a solids volume of 56.25 kgDS/hr.

TYPE | Maximum throughput by target function rate (kgDS/hr) | |||||

55% | 60% | 67% | 70% | 75% | 80% | |

101 | Due to the nature of sludge, it is difficult to guarantee moisture content. | 6 | 6 | 7 | 10 | |

102 | 12 | 14 | 16 | 20 | ||

201 | 10 | 12 | 14 | 17 | ||

202 | 20 | 24 | 28 | 34 | ||

203 | 30 | 36 | 42 | 51 | ||

204 | 40 | 48 | 57 | 68 | ||

401 | 35 | 40 | 45 | 50 | ||

402 | 70 | 80 | 90 | 100 | ||

403 | 105 | 120 | 135 | 150 | ||

601 | 80 | 100 | 120 | 140 | ||

602 | 160 | 200 | 240 | 280 | ||

[ Table C-1 ]

Since the solids volume is 56.25kgDS/hr, the appropriate type is 204 as shown in the table above. If the target moisture content of 80% is maintained when selecting the RT-204 type, the solids throughput will increase to 68kgDS/hr, but the cake production will increase due to the high moisture content.

TYPE | Maximum throughput by target function rate (kgDS/hr) | |||||

55% | 60% | 67% | 70% | 75% | 80% | |

101 | Due to the nature of sludge, it is difficult to guarantee moisture content. | 6 | 7 | 8 | 10 | |

102 | 12 | 14 | 16 | 20 | ||

201 | 10 | 12 | 14 | 17 | ||

202 | 20 | 24 | 28 | 34 | ||

203 | 30 | 36 | 42 | 51 | ||

204 | 40 | 48 | 57 | 68 | ||

401 | 35 | 40 | 45 | 50 | ||

402 | 70 | 80 | 90 | 100 | ||

403 | 105 | 120 | 135 | 150 | ||

601 | 80 | 100 | 120 | 140 | ||

602 | 160 | 200 | 240 | 280 | ||

[ Table C-1 ]

Since the solids volume is 62.5kgDS/hr, the appropriate type is 204 as shown in the table above. When selecting the RT-204 type, if the target moisture content is kept at 75%, the cake production is reduced due to the lower moisture content, but the solids throughput is reduced to 57kgDS/hr.

TYPE | Maximum throughput by target function rate (kgDS/hr) | |||||

60% | 65% | 70% | 75% | 80% | 85% | |

101 | Due to the nature of sludge, it is difficult to guarantee moisture content. | 0.25 | 0.3 | 0.35 | ||

102 | 0.5 | 0.6 | 0.7 | |||

201 | 0.5 | 0.6 | 0.7 | |||

202 | 1 | 1.2 | 1.4 | |||

203 | 1.5 | 1.8 | 2.1 | |||

204 | 2 | 2.4 | 2.8 | |||

401 | 2.6 | 3 | 3.5 | |||

402 | 5.2 | 6 | 7 | |||

403 | 7.5 | 9 | 11 | |||

601 | 5 | 6 | 8 | |||

602 | 10 | 12 | 16 | |||

Since the flow rate is 2.5㎥/hr, if the appropriate type is selected, 401 type is selected as shown in the table above. Since it is 204 and 402 types in terms of the amount of solids processed per hour, and 401 type in terms of flow rate, 401 type is selected for competitiveness, and 402 type is selected to have some spare capacity.

Influent sludge concentration: 8,000 mg/L (0.81 TP3T)

Inflow flow rate : 20㎥/day

Dehydrator Uptime: 8hrs/day

⊙ A, D region (VS/TS 85% or higher, target function rate 80%)

[Refer to Table A-1 and select the type that corresponds to a solids volume of 20 kgDS/hr.

TYPE | Maximum throughput by target function rate (kgDS/hr) | |||||

60% | 65% | 70% | 75% | 80% | 85% | |

101 | Due to the nature of sludge, it is difficult to guarantee moisture content. | 6 | 8 | |||

102 | 12 | 16 | ||||

201 | 10 | 13 | ||||

202 | 20 | 26 | ||||

203 | 30 | 39 | ||||

204 | 40 | 52 | ||||

401 | 35 | 40 | ||||

402 | 70 | 80 | ||||

403 | 105 | 120 | ||||

601 | 80 | 100 | ||||

602 | 160 | 200 | ||||

[ Table A-1 ]