Hello, this is the RK PR office.

We've received a lot of sales inquiries about sludge dewatering machines, sizing, and questions from different industries about which dewatering machine is right for their company.

The question asked by water treatment facility managers while considering other products was the convenience of operation according to their hard work.

Interpretation of water treatment based on the color of wastewater, sludge inflow and concentration, and proper capacity selection based on the guaranteed water content. The condition of sewage and wastewater is not always the same, and sludge has a different texture when touched by hand.

With more than 20 years of experience in the challenging sludge dewatering industry, RK has been conducting R&D with two development objectives, which have culminated in the unique technology of our centrifugal dewatering machines.

These two technologies will be applied to other larger models in the future through ongoing R&D, and will gradually evolve from three to four.

Korea, which is largely urbanized compared to its cramped landmass, is facing the same burden as Japan in terms of landfill costs for sludge disposal.

South Korea and Japan are less likely to urbanize, so there is less need for additional water purification plants and less need for additional sewage and wastewater treatment plants.

So, while there is a need for the industry to challenge the actual technology of sludge treatment to reduce operating costs, few progressive players are willing to jump on the bandwagon because of the low demand from urbanization.

On the other hand, Europe, Oceania, and mainland China have large areas of land and abundant landfills, so the energy that the soil needs to consume is low.

In the case of Southeast Asia, there is no demand for development because there is not much burden on processing costs. In the case of Southeast Asia, there is a need for technology transfer due to high urbanization demand, but at the same time, there is little infrastructure in related industries to proceed with technology development.

Recognizing the need to develop new technologies, ARK has spent years in R&D.

#Point1. Reduce maintenance and significantly reduce the probability of failure with lubrication-free bearings.

Centrifugal dehydrators currently available on the market utilize tapered bearings. These tapered bearings are susceptible to high temperatures due to their high RPMs and require periodic application of copper to ensure smooth operation of the centrifugal dehydrator.

Especially in the hot summer, the temperature vulnerability becomes more severe and requires careful management, like applying thermal copper to computer CPUs and GPUs. In winter, temperature differences can cause dew to enter the bearings or gas to form in the sludge, causing damage to the bearings.

This means that careful bearing inspection and copper application by a supervisor is essential, and it is not just a matter of applying copper to the bearings, but checking them for rotational power and life. Centrifugal dehydrators with tapered bearings have a separate thermometer.

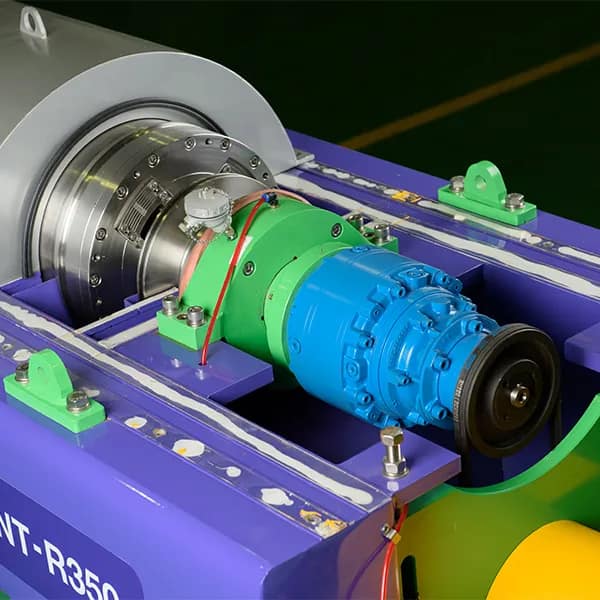

Recognizing the disadvantages of tapered bearings, ARK has developed ‘lubrication-free bearings" for some models through years of research and development.

No more thermometers, no more copper, no more lifechecks, and no more pressure on managers to be more sensitive in summer and winter.

In order to apply lubrication-free bearings, precision machining is required, and the mechanism must be tested tens of millions of times to design/manufacture to a tolerance of 5/100. After many internal discussions and countless tests since the decision was made, the result has been proven as a ‘Procurement Service Excellent Designated Product'.

Nowadays, smart farms are encouraged and activated in the farming industry with ITC technology, right?

The core of this is to reduce the number of farmers/production/distribution personnel and to enable automated and convenient crop production. On the industrial machinery side, smart operation/preventive maintenance/control should be easy.

RK took the first step with the ‘lubrication-free bearing' and was immediately recognized as an excellent product by the Public Procurement Service.

For smart operation of the sludge dehydrator, the stable maintenance of moisture content and adjustment of moisture content for automatic operation/unmanned operation are the advantages of the product, and we will strive to further expand this through R&D.

#Point2. Livestock centrifugal dehydrator uses FRP cover for easy management during installation and relocation

Environmental equipment is one of the most challenging installations. Hundreds of millions of dollars worth of environmental equipment is in a virtual building that hasn't been built, with unknown uncertainties from design to installation.

What if the building inspector didn't consider the window space for the sludge centrifugal dewatering machine before installing it? Installing a heavy dewatering machine requires a variety of equipment.

The cover is made of FRP to facilitate the installation of the heavy livestock dehydrator on the hoist after collecting installation errors experienced in environmental equipment installation for many years. RK does not accept past failures but improves them.

Even for the failures that can't happen in the future, we're going to data and aggregate them and turn them into better products.

The 10-year environmental facility manager is also a water treatment, and the technical department and board members all have a lot of experience in the water treatment field, having worked as public servants and engineers.

If you have any questions about sizing the product, please feel free to contact us on the KakaoTalk channel below.