Solutions in Water Environment

for People and Planet

Since our company was founded, we have been working tirelessly to develop the most realistic dehydrator in Korea. Belt presses and filter presses have been established as stereotypical dehydrator models by necessity, but there was a need to develop more technologically advanced screw presses and decanter centrifuges.

For years, sewage, wastewater, and water treatment plants have been dreaming of a sludge dewatering machine that would cost less to install, require less maintenance, and last longer.

The result is a multi-disc Screw-press is the value.

With more than 500 multi-disc screw presses delivered in Korea, ARK has become an almost unique developer.

Engineers from the last generation or two of senior dehydrator developers are now in their 70s, and it's unclear whether screw presses and advanced multi-discs will live on.

With a presence in Vietnam, ARK is bringing Korea's proud technology to Southeast Asian countries that are still in need of urbanization.

South Korea's soil energy is rising, as is Japan's. Europe and the United States have large territories, so there is less pressure on landfills, and Europe also has the option of dumping its trash in nearby Africa.

However, Japan and South Korea are small countries with little urbanization, which puts a lot of pressure on sludge treatment and landfills, and the energy required for soil to process landfill sludge is increasing.

In South Korea and Japan, sewage treatment plants, wastewater treatment plants, and water purification plants are replacing existing dehydrators and improving efficiency with facilities other than dehydrators to lower the cost of sludge treatment, so there is less need for R&D to pursue innovations that significantly change dehydrators.

Every area that requires sludge treatment already has an efficient plant configuration.

If you or your water treatment company is in charge of water treatment, you will also find that the most domestic and realistic product is a multi-disc screw press, except for some specialized sludge applications.

The need for multi-disc type lies in the advantage of saving facility cost when operating in Korea.

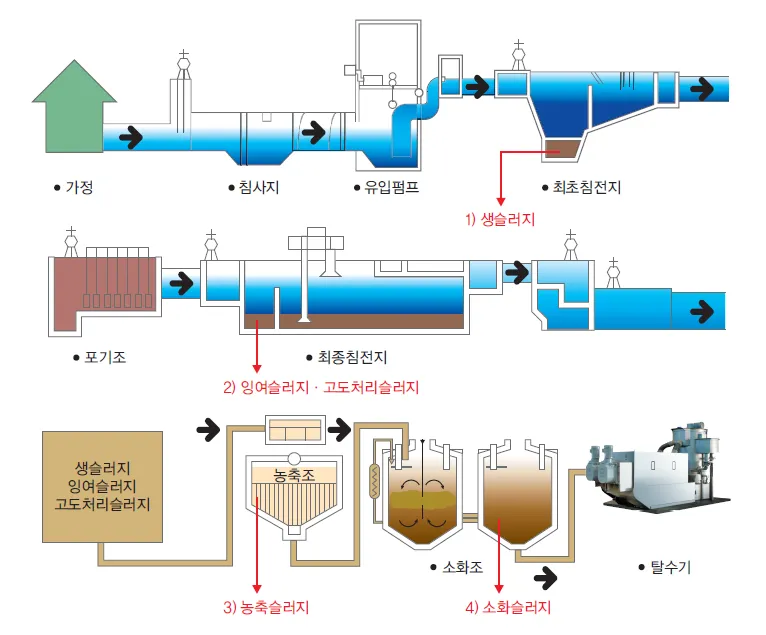

The multi-disc screw enables the direct withdrawal of low-concentration sludge from the wastewater tank facility during the treatment plant process. Eliminates the need for an odor control facility by eliminating concentrator reservoirs. Other dehydrators have low concentrations at withdrawal from the pond, requiring a concentration plant.

The low weight and compactness of the unit ensures ease of construction and convenience for the water operator. It also requires fewer braces and is hermetically sealed.

Decantercentrifuge They consume less power, have lower chemical and water consumption, and require less maintenance. And best of all, it's quiet.

The bottom line is that while decanter centrifuges make sense for large-scale sewage treatment plants, multidisciplinary disks are the best price/performance ratio for small and medium-sized enterprises in Korea.

ARK column: Screw Press (Multi-Disc) Model Selection Guide

ARKBLOG : https://blog.naver.com/sludge211