Dewatering machines are used to reduce the amount of moisture in sludge from sewage and wastewater treatment plants. Centrifugal dewatering machines are by far the most popular type of dewatering machine. Centrifugal dewatering machines utilize the principle of gravity to separate sludge into solids and water.

Types of dehydrators

Types of dehydrators include Decanter centrifuge(Centrifugal), screw press, belt press, and filter press dehydrators. Since each company has different equipment specifications and sludge characteristics (type/concentration), the dehydrators are mainly selected from major manufacturers. However, it is not suitable to select a dehydrator based on mere manufacturer recognition, and anxiety about the amount of sludge cannot be excluded.

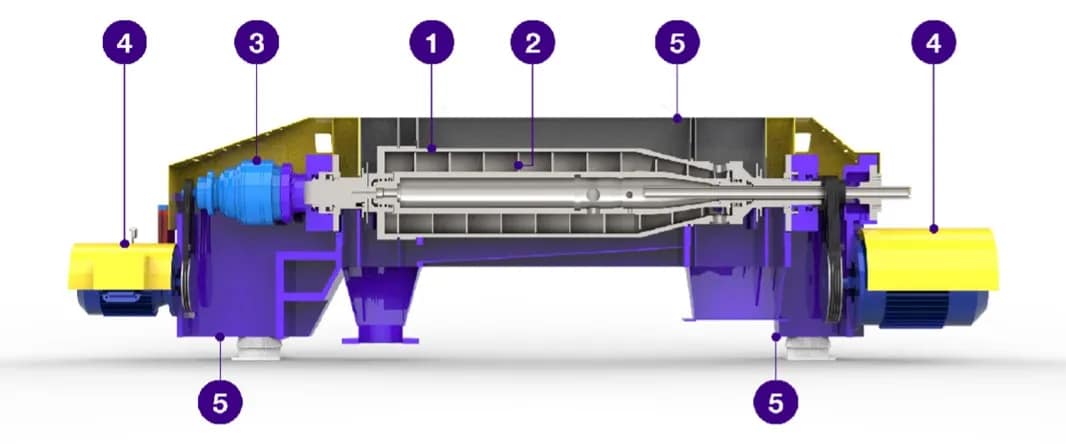

Centrifugal Dehydrator Structure

A centrifugal dehydrator consists of a bowl, screw cone bear, gearbox, drive, and body. The capacity of the dehydrator is directly proportional to the size of the inner diameter of the bowl and the outer diameter of the screw, and the specifications of each company are usually expressed in diameter. For centrifugal dehydrators, the specification is most often given in the last digit and looks like this Model - 360D, Model - 420D, Model - 300MTDI, Model - 350MTDI, Model - 3532, Model - R350, Model - R400, etc. Although the treatment capacity is listed according to these specifications, there are many differences in treatment capacity due to different experiences of each company, different sewage/wastewater sludge properties in different countries, different reference sludge concentration and organic content, etc. Therefore, it is difficult to list the treatment capacity on a uniform basis, but to make it more convenient for users, for example, the KO-360D has an internal diameter of 360 mm. As you can see, most of the specifications are organized in a specific format by internal diameter. So, if we organize the throughput by the inside diameter, it would look like this.

If the incoming sludge concentration is 1.0%

We believe that the inside diameter can handle up to 5 tons of D300, 10 tons of D350, 17.5 tons of D400, 25 tons of D450, 30 tons of D500, 35 tons of D550, 42 tons of D600, and 50 tons of D650, so we recommend choosing about 20% lower than this.

If the sludge concentration is 2.01 TP3T, then the

We estimate that the D300 3.5 tons, D350 5 tons, D400 9 tons, D450 20 tons, D500 25 tons, D550 30 tons, D600 35 tons, and D650 42 tons can be handled at maximum inside diameter, so we recommend choosing about 20% lower than this.

Sludge concentration is 3.0%

We estimate that the maximum inside diameter of the D300 is 2 tons, the D350 is 4 tons, the D400 is 7.5 tons, the D450 is 14 tons, the D500 is 20 tons, the D550 is 25 tons, the D600 is 30 tons, and the D650 is 36 tons, so we recommend choosing about 20% lower than this. Surplus sludge concentrations above 3.51 TP3T are difficult for polyamide and sludge to mix and react. However, raw sludge, mixed sludge (surplus + raw sludge), and sludge with high mineral content may be possible, but it is recommended to check the degree of reaction with polyamide in the field. Sludge throughput and moisture content vary depending on sludge type, concentration, PH, fiber content, mineral content, and other ionization levels, and the selection of the polyamide is particularly important. Since the throughput, water content, etc. vary greatly depending on these properties, it is recommended to consult with an expert unless it is a typical sewage/wastewater.