Domestic farmers who generate livestock wastewater and pig wastewater face many challenges. This is because they have to comply with environmental laws and regulations, as well as accurate management guidelines for wastewater.

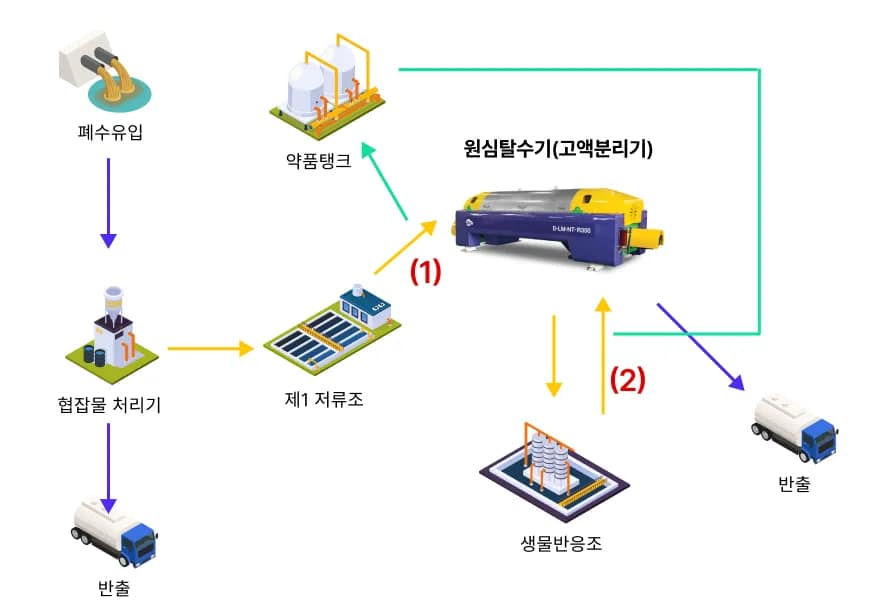

Domestic Swine unions, Korea Handon Association, Livestock Association and farms have always been concerned about odor reduction and livestock wastewater. They have introduced active manure treatment facilities, dehydrators and solid-liquid separators, purification in aeration tanks, recycling and discharging for pig sludge, and operating a resource circulation system by returning pig waste to composting companies.

With so much work and labor involved, odor concerns and the disposal of animal wastewater are a major concern for farmers and farmers with large numbers of animals.

This is because engineers who specialize in water treatment are hard to come by in today's world, and the odor often makes farms unappealing.

However, for farmers who are evolving and moving toward more advanced systems, centrifugal dehydrators are literally the easiest to manage for the company.

It takes a lot of research and development for Korean beef and pork companies to sell top-quality meat branded as superior breeding. The number of farmers in Korea is gradually decreasing, but on the contrary, the ability to upscale Korean beef farmers and pig farmers is not behind any other company in the world.

According to the law on livestock wastewater enacted by the Ministry of Environment, livestock wastewater has a higher concentration than other pollution sources such as domestic sewage and industrial wastewater.

Whether in the so-called ‘solid-liquid separation" applications or in the dewatering of sewage wastewater, centrifugal dehydrators require significantly less operator attention than filter presses and belt presses.

Selecting and operating a dehydrator that matches the sludge characteristics may be the most efficient purchase, but it can also result in a lot of labor for the operator.

We have installed many centrifugal dehydrators for corporate livestock farmers and pig breeding companies, and the high-efficiency centrifugal dehydrator is the most recommended for water treatment engineers who are getting harder to find overseas.

It is a product registered as an excellent designated product of the Public Procurement Service, optimized for the conditions of domestic farms after years of research and development, convenient to hang on the hoist with FRP cover, and resistant to gas burnout by adopting oil-less bearings, so there is no need to apply copper.

For organic matter above 351 TP3T, belt presses have an advantage in terms of moisture content, and for inorganic matter above 601 TP3T, filter presses have an advantage, but centrifugal dehydrators are overwhelmingly the most convenient to operate.

Most of our decanters, as well as our centrifugal dehydrators, are modeled on the basis of sewage wastewater data, so we will provide you with data according to the breeding scale and throughput of pig farms, pig farms, pig farms, etc.

Reservoir sludge concentration : 30,000 ~ 35,000mg/l

Concentration in bioreactor: 10,000 mg/l (Solid-liquid separation: use of polymer x, dehydration: use of polymer)

In the process of installing and operating livestock wastewater discharge facilities and treatment facilities, if a livestock farmer discharges pollutants in excess of the discharge water quality standards, an improvement order is issued to the livestock farmer and an economic burden is imposed on the livestock farmer to induce compliance with the standards and secure the effectiveness of the improvement order.

The discharge fee applies to livestock farms of a certain size and consists of a base fee and a treatment fee that is calculated according to the quality and quantity of the discharged water. The pollutants subject to the fee are organic matter (BOD) and suspended solids (SS).