Solutions in Water Environment

for People and Planet

Advantages and disadvantages of sludge dewatering. There are many types of Sludge Dewatering Machineand the most popular is Belt Press and Filter press. Here's the Screw Press , Decanter centrifuge which are more modern models. Each type of machine has its own advantages and disadvantages. ARKto provide some information to help you choose the right product.

Principles of centrifugation - Wikipedia

The quality and price of a product is a decisive factor for investors, and quality and price vary from manufacturer to manufacturer.

Today's market includes decanters Decantercentrifuge, 스크류 프레스, 벨트 프레스 및 필터 프레스를 포함하여 4가지 인기 있는 슬러지 탈수기 유형이 있습니다. 슬러지 유형, 슬러지 특성, 슬러지 탈수기 품질, 공급 업체, 기계 가격과 같은 올바른 슬러지 탈수기를 선택하기위한 기준 … ( More Criteria for Effective Sludge Dewatering Selection )

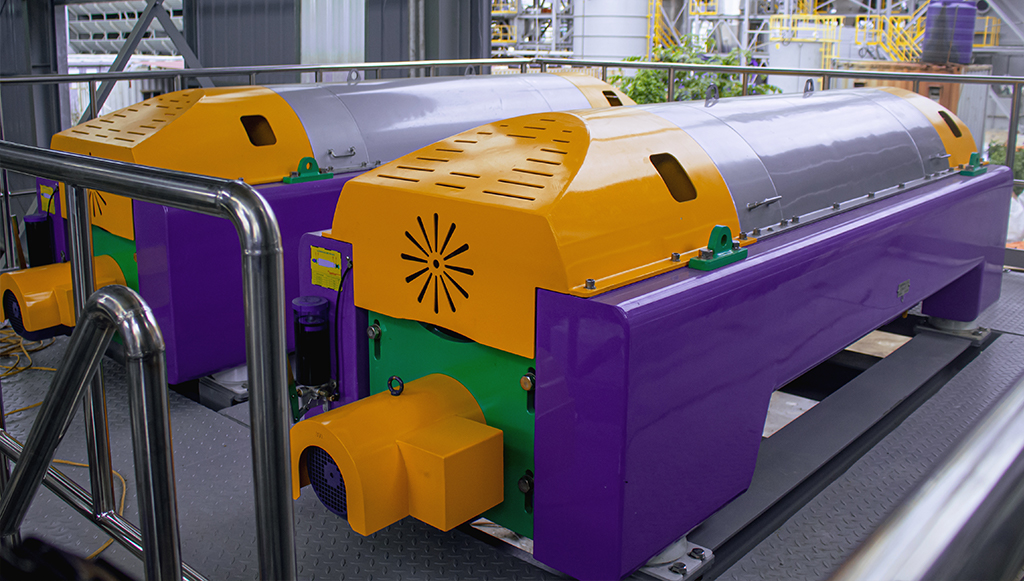

Decanter (Decanter Centrifuge Dewatering Machine) are the most advanced sludge treatment equipment available today. It is manufactured by many brands including ARK. ARK is proud to be the only company in Vietnam with its own factory to directly manufacture decanter decanter centrifuges.

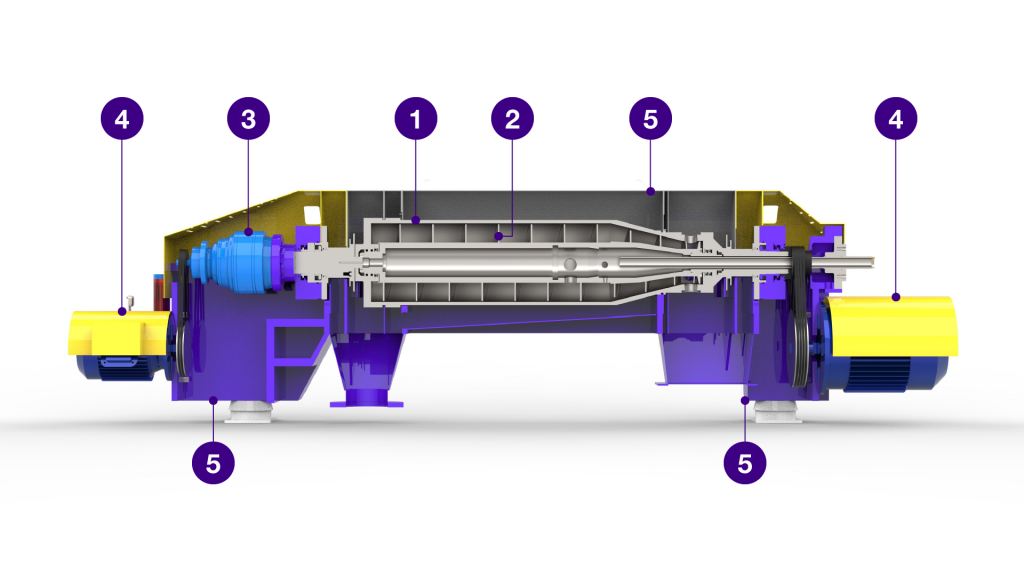

A decanter decanter centrifuge consists of a rotating platen, a rotating screw (with the same axis but different speeds), and a transmission box, The machine body is compact, but the centrifugal shaft has a very high rotational speed (3500 rpm). The device has a closed construction, which makes it easy to clean after use.

The flocculated sludge is fed into the main body, and the solid and liquid phases are separated by centrifugal force. The whole solid is extracted by the difference in shaft rotation speed. Water and sludge are discharged as two different outputs.

Decanter Centrifugal Dehydrator Structural Diagram

Pros

Cons:

Decanter centrifuges are commonly used in domestic/industrial wastewater treatment systems. In particular, this device can treat livestock farm waste.

The cost depends on the volume of sludge to be treated for which you will have the appropriate capacity. The price difference between the models ranges from $10,000 to $40,000.

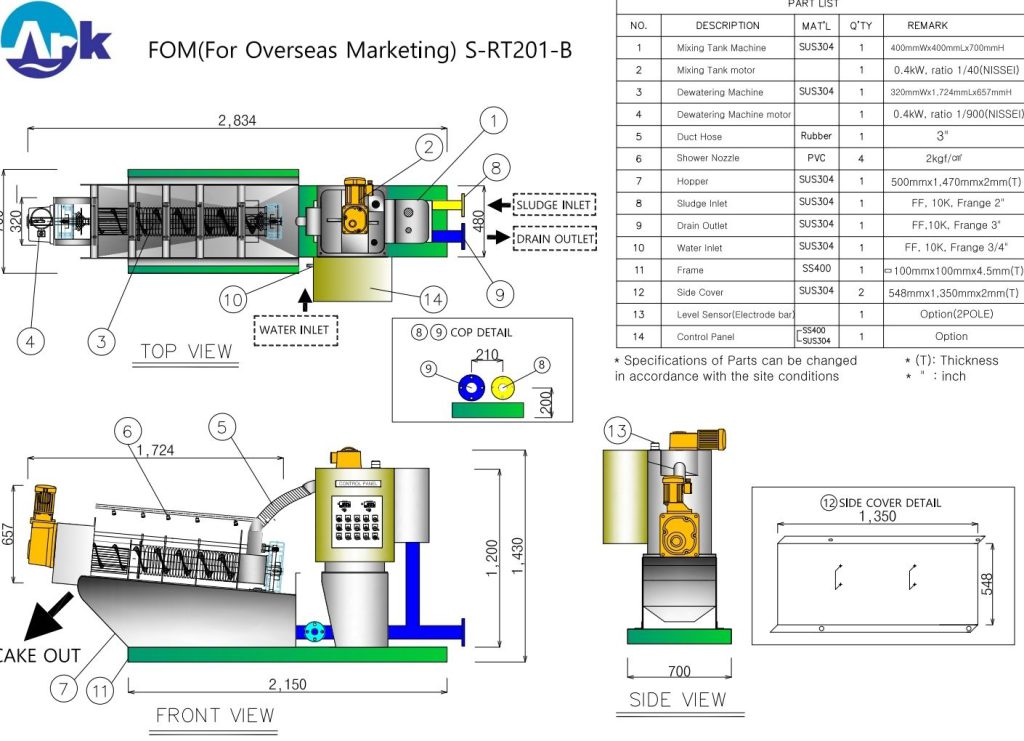

Screw press (multi-disc screw press dehydrator) It is a new generation sludge dewatering machine with many outstanding features. It is suitable for different kinds of sludge and widely used in sludge treatment.

Structural drawing of a screw press, type SV-RT

The main parts of a screw press consist of a screw, filter, sludge-polymer reaction tank, and body. It combines a sludge-polymer reactor with a dewatering unit and has a compact structure. The closed construction also makes the equipment durable and easy to maintain.

The inlet sludge is concentrated and at the same time compressed for dewatering. The filter section consists of movable and fixed rings that perform the function of turning over the sludge and separating the sludge from the water. The filtered sludge is then moved and pressurized by a rotating screw where it is dried at the outlet. The liquid phase is separated by gravity between two adjacent disk gaps.

Pros

Cons:

Screw presses are used for many different types of sludge. Even for high viscosity sludges such as food processing, dairy processing, etc.

There are 3 types of screw presses: S-ST, S-RT, and SV-RT. The price of SV-RT is considered the cheapest and widely used in Vietnam. With the same capacity, the difference between the three types is from $3,500 to $10,000.

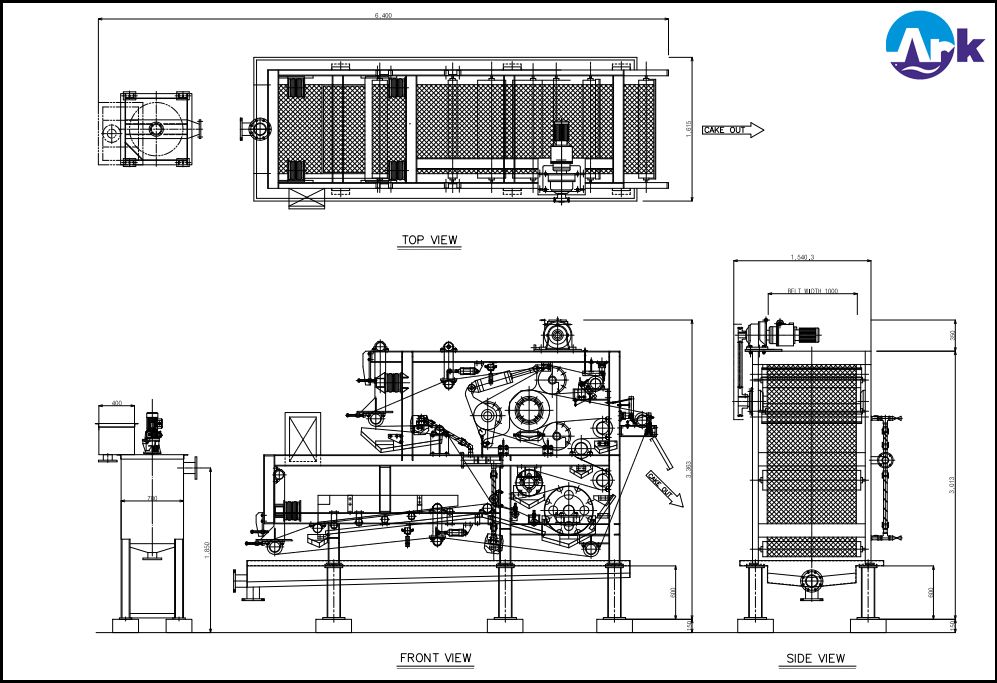

Belt Press Dewatering Machine (Belt Press) is a sludge treatment equipment that has appeared for a long time and has been trusted by many investors. The machine has a simple structure, which is easy to use and maintain. The device can change the water content of the sludge when adjusting the conveyor.

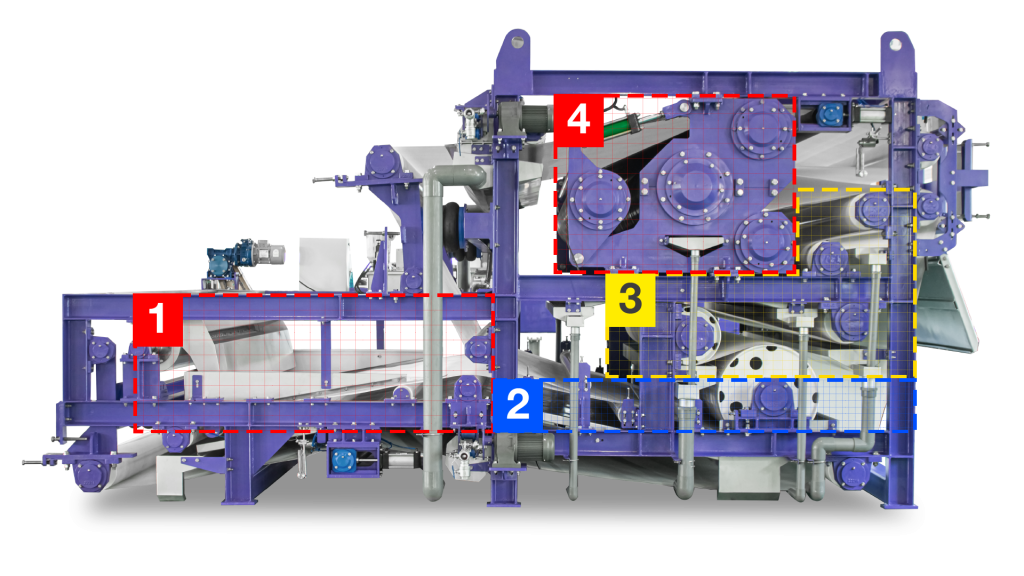

Schematic of a belt press

The belt press consists of the following main parts: rotating belt, sludge squeezing roller between upper and lower belt, and machine body. The belt press is designed separately from the sludge polymer reaction tank; it has an open structure. The machine has many auxiliary devices, such as gears, high-pressure cleaning system; it also has a large size and weight.

The flocculated sludge is fed into the space between two different belts. The belt presses the sludge with high pressure generated by multiple rollers.

Pros

Cons:

Belt presses have been widely used for a long time. They are particularly suitable for sludge that is low in cost and not too dry. Some industries often use belt presses, such as the pulp and paper industry, household wastewater treatment systems, etc.

벨트 프레스는 다른 슬러지 탈수기보다 저렴합니다. 용량이 다른 모델 간의 차이는 약 $ 7,000 – $ 10,000입니다.

Filter-presss (Filter Press Dewatering Machine) is a sludge treatment machine that produces high-drying sludge cake. This device saves a lot of collection and transportation costs. It has been chosen by many investors for small and medium-sized processing systems.

The filter press consists of the following main parts: hydraulic cylinder, drip tray, plate, and frame. The Filter-press is designed separately from the Sludge-Polymer Reaction Tank and has an open structure. The machine is designed with many auxiliary devices.

The coagulated sludge (depending on the type of sludge, which may or may not require the use of polymer) is fed into the frames and pressurized. The sludge is pumped continuously until all the frames are full. The machine stops at that time.

The sludge is dewatered with pressure from a hydraulic cylinder. The fenders move in opposite directions on a steel frame that holds the sludge. The filter press runs in batches for about 4-5 hours per batch.

Pros

Cons:

The filter press is a simple mechanism and is very effective for many types of sludge, including sewage sludge from textile and dyeing production, steel production, etc. However, it is not suitable for large volumes of sludge due to limited batch operations. mud.

The average price of a filter press is between $5,000 and $10,000. .

Today, many brands offer the above types of sludge dewatering machines. However, ARK is the only factory that can produce all kinds of sludge dewatering machines at favorable prices.

With 30 years of experience in Korea and 10 years in Vietnam, ARK is always aiming for sustainable value with our customers.

Our production lines follow the most modern technology in Korea, imported directly from the USA, UK and South Korea. Confirms ISO 9001:2015 standard.

ARK has a team of highly qualified engineers with many years of experience. The skilled workers always try their best to provide the best products.

ARK's sludge dewatering machines are recognized not only in Korea and Vietnam, but also abroad. ARK's reliability is proven by positive customer reviews.

ARK is committed to providing you with 100% new products, which are produced directly in Vietnam according to Korean technology. We are always ready to provide machines and support on time. In addition, every customer wants to use ARK's sludge dewatering machine honestly and see the economic benefits. We offer test run service for all types of sludge.

Contact us today for an enthusiastic and responsive consultant.

[block id=”footer-post”]