Solutions in Water Environment

for People and Planet

Hello, I'm Minhee Hwang from the public relations office.

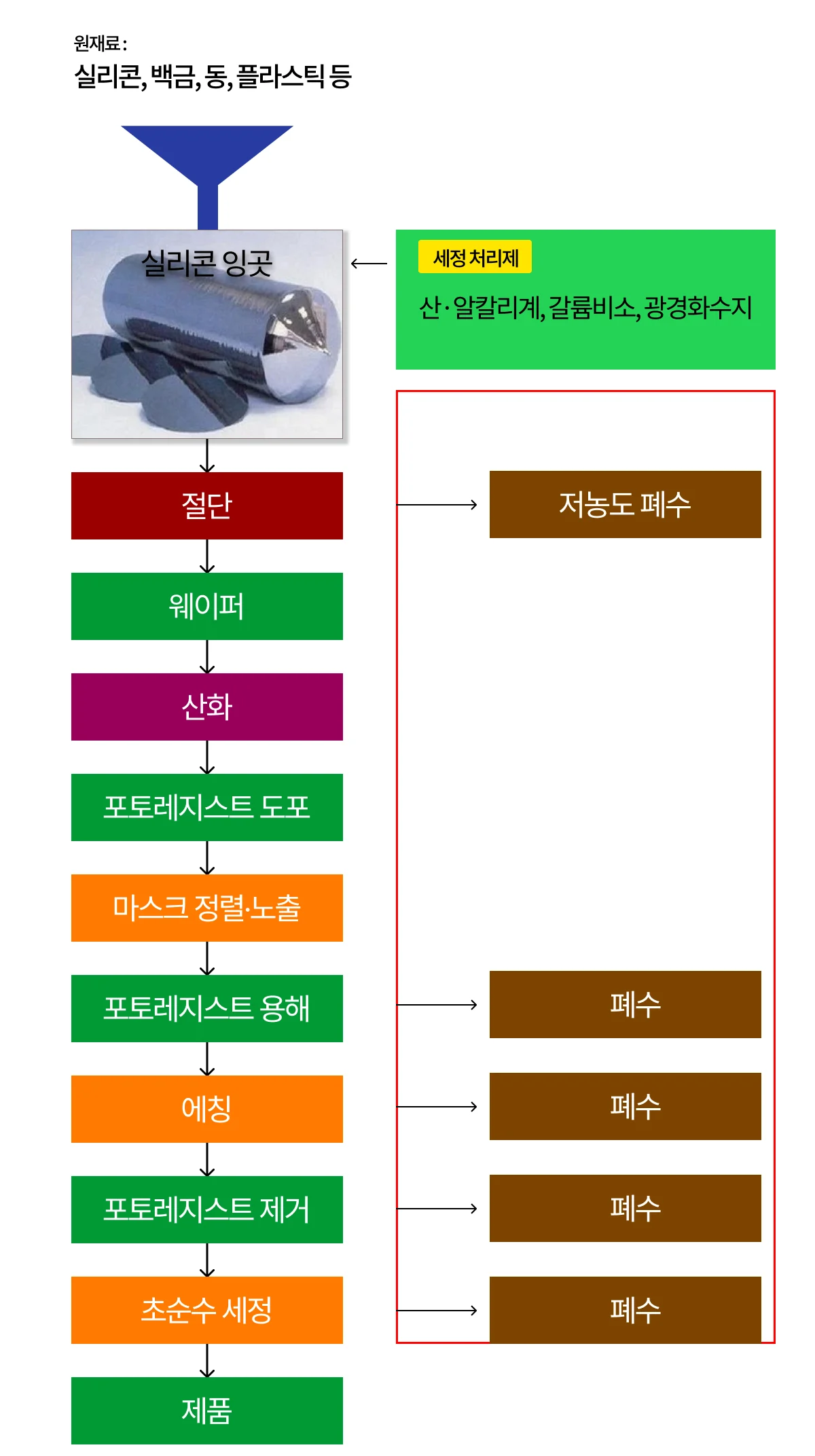

Today, I would like to introduce wastewater treatment in the electrical and electronics industry, which is a core industry in Korea. The electrical and electronics industry, which is mainly related to the semiconductor process, uses ultra-pure water (UPW) for cleaning semiconductors, displays, and nano-research fields among other electronic components.

Ultrapure water is literally the purest water and is closest to the resistivity level (18.25㏁.cm). Even microscopic debris can interfere with semiconductor current flow, and ultrapure water is free of such debris.

Ultrapure water used to be a Japanese monopoly, but now South Korea has ultrapure water technology as well, and the ultrapure water process requires a 24-step process including ultraviolet oxidation and ion exchange.

Semiconductors are manufactured in ultra-clean environments because they need to be ultra-pure, as any impediment to the flow of current from microscopic particles can cause significant losses in the critical functions of electronics.

Ultrapure water used in the process of washing silicon wafers when making semiconductor wafers. And other electrical and electronic wastewater.

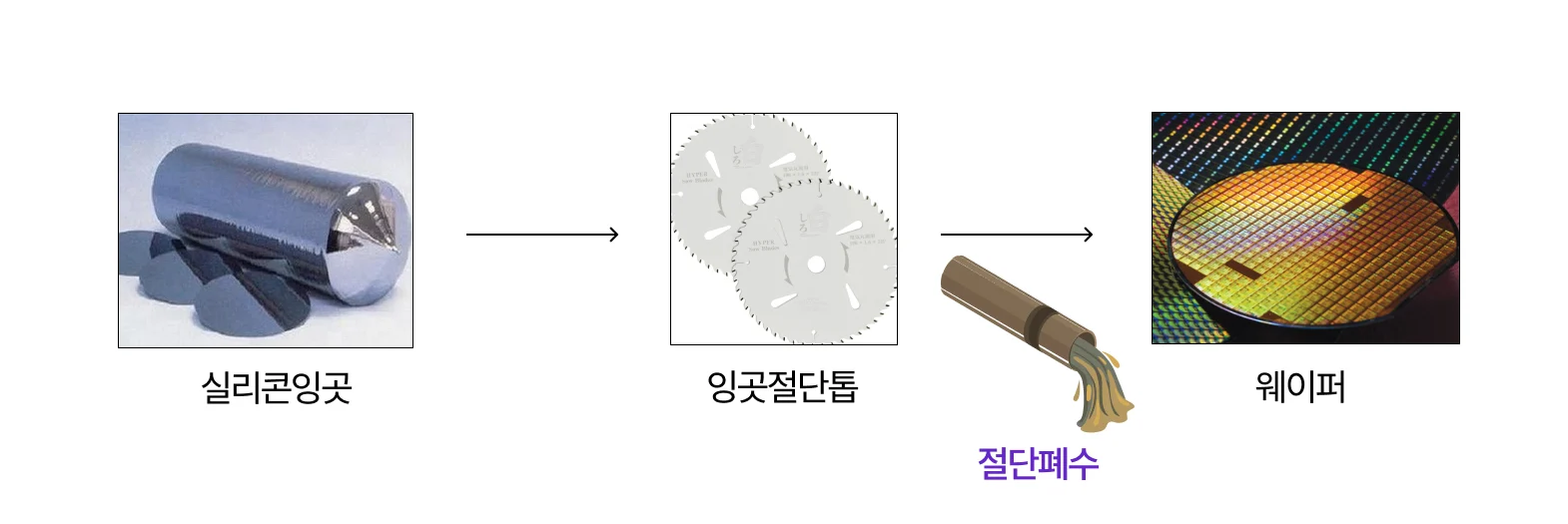

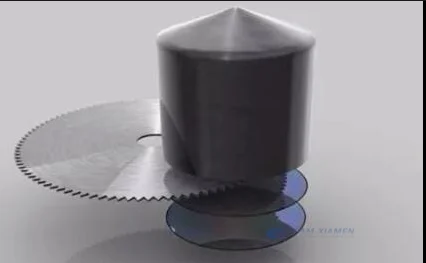

Silicon is extracted from sand as silicon crystal growth technology, in which silicon is melted to a high temperature into a solution and cooled to a single crystal, which is then made into an ingot.

This ingot is then saw-cut to produce semiconductor wafers, which generates primary wastewater.

The production process of electrical and electronic products varies from product to product, but they are all subjected to ‘cleaning’ with ‘ultra-pure' water, and wastewater is generated during this process.

| Separation | pH | Contents |

| Low-concentration wastewater | Acidic 3-5 | Fluoride ion, nitrate, phosphate, silica, organic matter (BOD, COD), ammonium ion, hydrogen peroxide |

| High Concentration Wastewater | Sulfuric acid, hydrochloric acid, nitric acid, hydrogen peroxide, fluorine, acid ammonium fluoride, silicone powder |

Suspension water from primary processing: This refers to water containing silica from cutting the primary ingot and processing the wafer in the above process. It is highly turbid but contains few soluble chemicals, so it is purified using membrane filtration technology and a large part of it is reused.

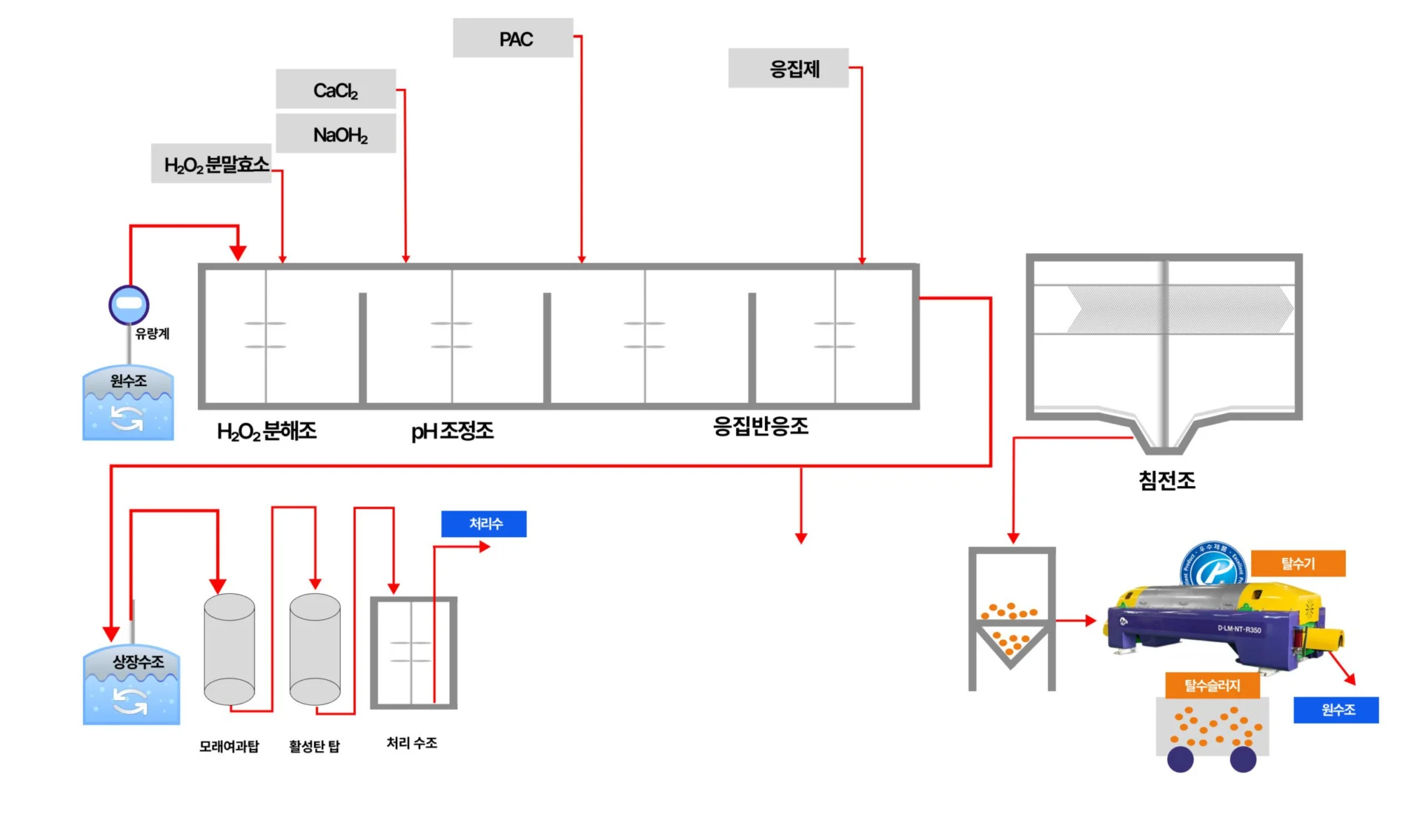

Since the wastewater contains hydrofluoric acid and hydrogen peroxide, the enzyme catalase is used to break it down, followed by neutralization/flocculation treatment with calcium chloride and calcium hydroxide.

The flocculation precipitation byproduct is calcium fluoride sludge, which is sold to cement manufacturers, and the treated water is sand filtered and activated carbonized before being reused.

The above facility process is an inorganic process, and in the case of organic system, additional facilities such as flow adjustment tank, aeration tank, sand filtration tower, activated carbon tower, etc. are required to decompose flocculation treatment water into biological treatment activated sludge.

List of domestic pure/ultrapure water facilities

| Separation | Business name | Phone number | Homepage |

| Net Equipment | Kurita Hansu Co. | 031-789-1700 | View |

| Pure/ultrapure | WelchronHantech | 031-350-8900 | View |

| Ultra-pure water facilities | Environment | 053-763-1911 | View |

| Ultra-pure water facilities | JINYUNG ENTITY | 031-457-6565 | View |

| Ultra-pure water facilities | (Corea WaterTrol | 02-943-9623 | View |

| Ultra-pure water facilities | Thawing Technology | 031. 386. 3901 | View |

| Ultra-pure water facilities | AcroWaterTech | 070-5129-6501 | View |

| Ultra-pure water facilities | Techwin | 043-261-8114 | View |