Solutions in Water Environment

for People and Planet

Hello, I'm Sohee Jeon, a manager at ARK. Continuing our series on lithium-ion batteries, today we'll be looking at the paper industry, which is in the midst of a global R&D battle to replace plastic with nanocellulose.

We'll start with information on wastewater treatment and end with the recycling of lignin and black liquor. We will continue the series with the following parts.

vol.1 > From paper and pulp wastewater treatment to nanocellulose and bio-aerosols

vol.2 > Domestic paper and pulp companies Hansol Paper and Murim P&P and overseas resource recycling cases (tentative)

vol.3 > Overseas research activities related to paper/pulp black liquor (tentative)

vol4. > Introduction of environmental facility construction companies and contractors related to paper wastewater in Korea (tentative)

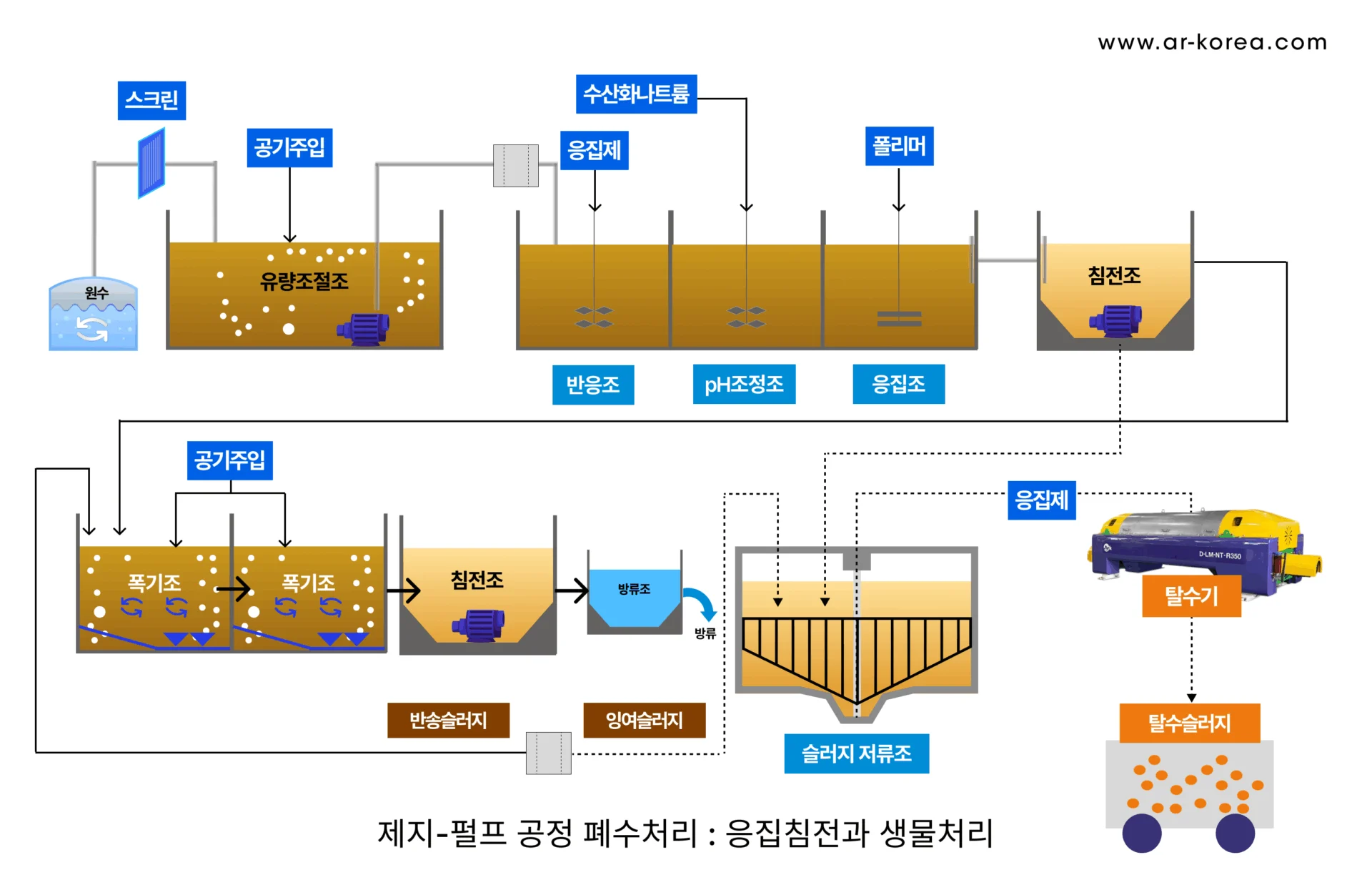

Flocculation, pressurized flotation, and activated sludge methods are used.

Paper pulp production produces black liquor during lignin separation, which is too high in BOD to be treated by popular and common water treatment methods. Previously, black liquor was collected and recycled to industries such as fuel use or nylon raw materials, but recently, the value of recycling black liquor is gradually increasing due to various research and development.

The most common treatment methods for paper pulp wastewater with suspended solids are flocculation or pressurized flotation combined with biotreatment for organic matter.

In the case of pressurized flotation tanks, the pH is adjusted to around 8 with aluminum sulfate/polyaluminum chloride, and the flotation flocs are sent to the sludge tank for biotreatment in the aeration tank.

‘Have you ever heard the phrase ’it takes 100 tons of water to produce one ton of paper‘? Paper and pulp products, which you may only think of as A4, are as ubiquitous in our lives as plastics. While plastics in general have become 'biodegradable', the environmental and biological impacts of microplastics are still relatively unknown, and the perception is that they are not as good for the environment as the image of trees.

The paper and pulp industry as we know uses a lot of water and heat energy, and the efficiency of recycling waste heat and waste liquids has been raised to a considerable level, and furthermore, the black liquid generated in the process of separating lignin, which keeps the hardness of wood, and cellulose, which is actually used for paper pulp, is also used as incineration fuel, and the separated lignin is also being researched and developed to produce new biofuels and ‘nanocellulose' by recycling it worldwide. Therefore, trees are eco-friendly with nothing to waste.

Wastewater treatment in paper pulp is very important, but when it comes to resource recycling beyond wastewater treatment, nanocellulose technology is getting more attention than lignin and cellulose.

The global technology leaders in nanocellulose are Canada, Japan, Finland, and Norway, which are leading the way in manufacturing technology and research and development (R&D). Major companies include Kruger Inc. in Canada, Nippon Paper Group in Japan, Beauregard in Norway, and Fiberlean Technologies in the UK. Canada is a global leader in nanocellulose technology, and its use in a variety of applications is growing.

Korea is another country where Murimphy & P excels in technology.

Therefore, this series will start with paper and pulp wastewater treatment, but we will also share the environmental talk with you by providing insights into the resource recycling efforts of Korea's proud paper and pulp manufacturers and nanocellulose.

First, the domestic major paper and pulp companies are the white cardboard industry's Hansol Paper, Clean Country, Hanzhong PaperThe printing paper is manufactured by Hansol Paper, Forest Paper, MurimP&P and more.

It is also a highly technologically advanced and competitive industry with excellent performance of domestic companies that have become world-class luxury papers. It has become an important everyday consumer product with the growth of e-commerce, while being eco-friendly and contributing significantly to ESG management.

Since the COVID-19 pandemic, the rapid growth of contactless distribution has brought many changes to our society. In particular, the expansion of online shopping markets and delivery systems has dramatically changed the way consumers buy. In this environment, the demand for white paperboard has increased significantly. While the production of traditional printed paper has decreased globally due to the one-to-one digital machine replacement, the market for e-commerce paperboard used for parcel boxes and thermal paper has increased.

White paperboard is used as a high-end packaging material in various fields such as confectionery, pharmaceuticals, cosmetics, and more, enhancing the quality of products. In 2020, sales reached approximately KRW 189.5 billion, an increase of 6.71 TP3T year-on-year, followed by KRW 204.4 billion, an increase of 7.91 TP3T in 2021, and KRW 227.3 billion, an increase of 11.21 TP3T in 2022. This growth is attributed to consumers' desire for high-quality packaging.

Currently, whiteboard is gaining more emphasis as an alternative to plastic due to growing environmental concerns. The market outlook for the future is very positive and it is expected to become a sustainable packaging solution.

That's why it's important for everyday paper, paper and pulp consumers to pay attention to wastewater treatment.

South Korea's paper and pulp industry has experienced significant growth since 2020, which can be attributed to the following factors.

Celluloseplays a critical role in the paper and pulp manufacturing process, and its utilization is expanding throughout the industry. An understanding of cellulose is essential for a deeper understanding of the paper and pulp industry. Below, we'll discuss the role and uses of cellulose in more detail.

Do you know the secret to keeping wood hard? It's a friend called lignin. Along with cellulose, lignin is the main component of wood, and it's responsible for giving trees their rigid backbone.

Unfortunately, in order to make the paper we use, we need to remove the lignin, which is just the cellulose, to make the soft pulp that makes paper. So for a long time, lignin was simply treated as a waste material, because its complex structure made it difficult to utilize. And every year, huge amounts of lignin were being thrown away around the world.

But with the recent interest in lignin, we're seeing a remarkable transformation! What used to be a discarded material is now a treasure trove of new value. There's a lot of research being done on lignin to create a variety of products, and more and more of them are actually being commercialized.

So what can you make with lignin? Nylon raw materials and fuel industries such as vanillin and carbon monoxide.

#Lignin #Eco-friendly #Biomass #Sustainable Development #New Materials

Since it is made by recycling discarded waste paper and soaking it in water, it contains various foreign substances, printed ink, glue, metal stemplers, and harmful substances, and wastewater containing these substances is generated, and surfactants, hydrogen peroxide, formamidine, sodium silicate, etc. are used to separate them.

Additional ingredients based on paper type: Calcium carbonate, starch, ink residue, dyes, etc.

For waste paper pulp : Printed ink, office stampers, etc.

The combination of flocculation or pressurized flotation with biotreatment to treat organic matter is popular, and the black liquor has a high BOD, so after incineration, it is attempted to be recycled in various ways such as fuel use or nylon raw materials.

Lignin-containing wastewater, chlorinated wastewater, sulfide wastewater, textile residue, etc. The black liquid is not treated with BOD and is used for incineration/recycling.

펄프 과정에서 사용된 화학물질과 리그닌, 기타 유기물의 혼합물인 흑액은 공정 내에서 수집된 폐수입니다. 일반적으로 높은 BOD(생화학적 산소 요구량) 및 COD(화학적 산소 요구량)를 가지고 있습니다.u003cbru003e흑액은 환경에 유해할 수 있으며, 적절한 처리 없이 방류할 경우 오염 문제가 발생합니다. 이 흑액은 대개 열 에너지를 회수하는 방법으로 재활용되기도 합니다.

Cellulose, which accounts for 45~501 TP3T of pulp material, is the main component of plants. It is a substance that is separated from lignin, which maintains the hardness of wood, and is left over after processing the black liquid, which has the characteristics of a sticky grass-like state, and is called nanocellulose, which is obtained by separating it with ultra-high pressure of a water jet or chemical treatment with nano-density, and is being applied to various fields.

나노셀룰로오스는 친환경 소재로서 다양한 분야에서 활용되고 있으며, 지속적인 연구개발이 이루어지고 있습니다. 실제 상품화된 활용분야와 최근 연구분야를 살펴보겠습니다.상품화된 활용분야u003cbru003eu003cbru003eu003cstrongu003e포장재u003c/strongu003eu003cbru003e나노셀룰로오스는 식품 포장용 투명 필름으로 개발되어 사용되고 있습니다. 이 필름은 물에 잘 젖지 않고 생분해가 가능한 특성을 가지고 있어 환경 친화적입니다u003ca href=u0022https://blog.naver.com/kofst_news/223072070647u0022 target=u0022_blanku0022 rel=u0022noreferrer noopeneru0022u003eu003c/au003e.u003cbru003eu003cbru003eu003cstrongu003e전자기기 외장재u003c/strongu003eu003cbru003e바이오 폴리카보네이트 형태로 스마트폰과 같은 전자기기의 외장재로 활용되고 있습니다u003ca href=u0022https://blog.naver.com/kofst_news/223072070647u0022 target=u0022_blanku0022 rel=u0022noreferrer noopeneru0022u003eu003c/au003e.u003cbru003eu003cbru003eu003cstrongu003e영유아 용품u003c/strongu003eu003cbru003e독성이 낮은 특성을 활용하여 영유아 장난감과 젖병 소재로 사용되고 있습니다u003ca href=u0022https://blog.naver.com/kofst_news/223072070647u0022 target=u0022_blanku0022 rel=u0022noreferrer noopeneru0022u003eu003c/au003e.최근 연구분야u003cbru003eu003cbru003eu003cstrongu003e의료 분야u003c/strongu003eu003cbru003e나노셀룰로오스의 생체적 안정성을 활용하여 임플란트와 인공뼈 소재로의 연구가 진행 중입니다u003ca href=u0022https://blog.naver.com/kofst_news/223072070647u0022 target=u0022_blanku0022 rel=u0022noreferrer noopeneru0022u003eu003c/au003e.u003cbru003eu003cbru003eu003cstrongu003e화장품 산업u003c/strongu003eu003cbru003e국내에서 나노셀룰로오스를 화장품 소재로 활용하기 위한 연구가 활발히 이루어지고 있습니다u003ca href=u0022https://blog.naver.com/kofst_news/223072070647u0022 target=u0022_blanku0022 rel=u0022noreferrer noopeneru0022u003eu003c/au003e.u003cbru003eu003cbru003eu003cstrongu003e전자 산업 / 리튬-이온전지u003c/strongu003eu003cbru003e플렉시블 전극 개발을 위한 연구가 진행 중입니다u003ca href=u0022https://blog.naver.com/kofst_news/223072070647u0022 target=u0022_blanku0022 rel=u0022noreferrer noopeneru0022u003eu003c/au003e.u003cbru003eu003cbru003eu003cstrongu003e필터 기술u003c/strongu003eu003cbru003e나노셀룰로오스를 이용한 고성능 필터 개발 연구가 이루어지고 있습니다u003ca href=u0022https://blog.naver.com/kofst_news/223072070647u0022 target=u0022_blanku0022 rel=u0022noreferrer noopeneru0022u003eu003c/au003e.u003cbru003eu003cbru003eu003cstrongu003e자동차 산업u003c/strongu003eu003cbru003e나노셀룰로오스 복합 수지를 이용한 자동차 구조재 개발이 주목받고 있으며, 자동차 경량화를 목표로 한 프로젝트들이 진행 중입니다u003ca href=u0022https://blog.naver.com/yanokorea/221107679501u0022 target=u0022_blanku0022 rel=u0022noreferrer noopeneru0022u003eu003c/au003e.u003cbru003eu003cbru003eu003cstrongu003e바이오 복합재u003c/strongu003eu003cbru003e셀룰로오스 나노 섬유의 높은 종횡비와 강도를 활용하여 바이오 복합재 분야에서 강도 향상을 위한 충전제로서의 연구가 활발히 진행되고 있습니다u003ca href=u0022https://kurn.korea.ac.kr/cmm/fms/FileDown.do?atchFileId=STM_0000000000000644u0026amp;fileSn=2u0026amp;is=Yu0022 target=u0022_blanku0022 rel=u0022noreferrer noopeneru0022u003eu003c/au003e.나노셀룰로오스의 산업화를 위해 품질관리, 생산성 향상, 산업 표준화, 인증 절차 개발 등에 대한 연구도 지속적으로 이루어지고 있습니다u003ca href=u0022https://www.knongnews.com/news/articleView.html?idxno=19427u0022 target=u0022_blanku0022 rel=u0022noreferrer noopeneru0022u003eu003c/au003e. 이러한 다양한 연구와 개발을 통해 나노셀룰로오스는 앞으로 더 많은 분야에서 활용될 것으로 예상됩니다.