Hello, I'm Minhee Hwang from the public relations office.

Recently, there are many news about the challenges of overseas construction projects due to the domestic recession. However, statistics from the Overseas Construction Association's Overseas Construction Integrated Information Service show that the decrease of about 481 TP3T from last year is indicative of the difficult situation.

Many construction companies have repositioned themselves in the environmental industry, expanding into markets in Southeast Asia, the Middle East, and South America, as well as into lithium and nickel mining concessions.

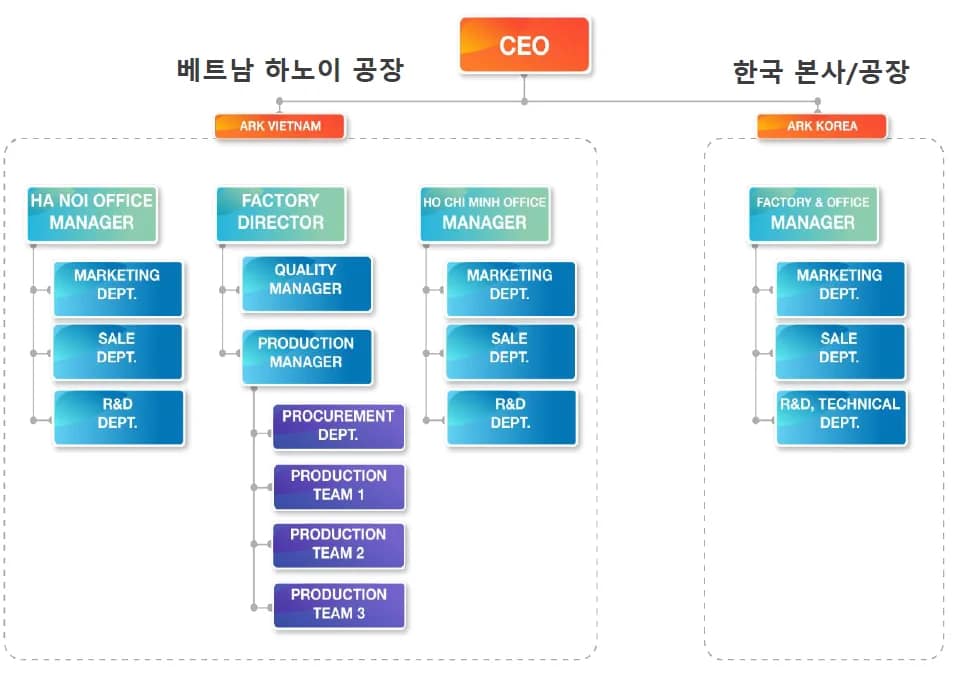

ARK Vietnam Co.,Ltd was established in 2011 with the establishment of a factory in Hanoi, Vietnam, and has been in business for 24 years.

The company has accumulated more than 1.5 million dollars in overseas projects and is developing technologies to further advance the current centrifugal dehydrator, transforming ‘automatic operation‘ into 'real automatic operation' through AI while reducing carbon.

Every water treatment engineering company is different.

What is the essence of a dehydrator developer, and what is the essence of an a la carte? It can be divided into the former and the latter.

Previous generations of environmental engineers learned Japanese municipal sewage treatment technology and developed it into know-how that suits Korea's unique characteristics.

At that time, we used ‘MicroorganismsI've been reading, applying, experimenting, and accumulating data.

And as manufacturing developed, skilled engineers with very precise tooling became skilled enough to develop their own centrifugal dehydrators.

In other words, the essence of a dehydrator development company can be divided into two types: a company that is more based on microbial knowledge and experience from the perspective of dehydration = microorganisms, and a manufacturing-based engineering company that gains knowledge in the field of microorganisms.

The essence of our organization is the former. Company executives have a strong understanding of the ‘microbiome' and the ability to adapt to local markets. Decanter centrifuge I know how to operate it.

Most environmental equipment companies are not familiar with the ‘microbial mechanisms‘ of "dehydration" because environmental engineering requires a high level of biology and chemistry, and mechanical engineering requires electronics, automation, and hydrodynamics.

A dehydrator is a machine in the engineering field, but we must not forget that microorganisms are at the base of the environmental ‘how to‘.

As cities become more advanced and the rate of urbanization reaches the late 90%, social structure changes and corporate governance changes, it is a very difficult challenge to train environmental engineers and cultivate younger generations.

Sometimes, EPC companies question or criticize the performance of the dehydrator when they see poor dewatering.

This is because in the formula dewatering = microorganisms, wastewater treatment plants operate differently by season, by wastewater composition, and by microorganism type, and there is a ‘factor of thumb" to be judged.

After at least five years of trial and error, the operator at that wastewater treatment plant gains an understanding of dewatering, and when they move to another wastewater treatment plant, they will obviously face different variables and their experience factor will change a bit.

That said, wastewater and microbes are a very challenging field.

AI has already been used in Japan to learn about microorganisms by wastewater treatment plant and season, enabling ‘predictive wastewater treatment" and accurate wastewater treatment plant operation.

As a group with a strong understanding of microorganisms, ARK is the developer of a dehydrator that has won the title of the Public Procurement Service's Excellent Quality Product and one of the few companies that now produces its own screw presses for domestic flights.

Our concern is that even environmental equipment companies are faced with the difficulties of wastewater treatment, ignorance of microorganisms, and sometimes ‘blaming the machine'.

However, this is a problem that every dehydrator developer, both domestic and international, faces.

Germany is the so-called ‘price setter'. They have set the market price by using the best materials and investing in research and development. Like China, they have emulated the UK in the early days, planting spies and adhering to a low-quality policy, but like everywhere else, they use expensive materials in their water treatment products.

When Germany came to Korea, they installed a centrifugal dehydrator. However, it didn't work well.

The algae bloom at the Paldang Dam was causing the water to dehydrate.

The best product in the world is still a useless spring that can't be drained if you don't know how to drive it in your country.

No, it's the same as the German example above. If you take a product from Korea and run it in Vietnam, it won't dehydrate as well as if you run it in Indonesia.

This is because different countries have different industrial wastewater compositions, different microorganisms, seasonal changes in wastewater composition, changes in microorganisms due to rainwater inflow, and many other variables.

So the most important thing is experience. The international water treatment market is one of the most challenging markets because the water environment data is different and varies from country to country.

Treatment plant management personnel have a lot on their plate. They need to have experience with sludge, wastewater treatment theory, dewatering machines, and an understanding of microorganisms.

Sometimes they are overstaffed with sacks due to an aging dehydrator, sometimes they are consulted for an unknown wastewater phase.

In the future, dehydration will be automated, and AI driving will not only drive optimally, but will also make up for the lack of knowledge and experience that is too often required.

Currently, RK is planning to conduct AI-based R&D to solve the lack of experience factors that will reduce the amount of chemicals used by automatic operation of dehydrators, optimize operation according to real-time sludge, reduce power consumption, and reduce the efforts of managers.

To summarize, here's why you should join us.

Undoubtedly, the most important thing you need when working on an international project is an ‘experienced partner’. An organization made up of people who have experience with different wastewater in different countries.

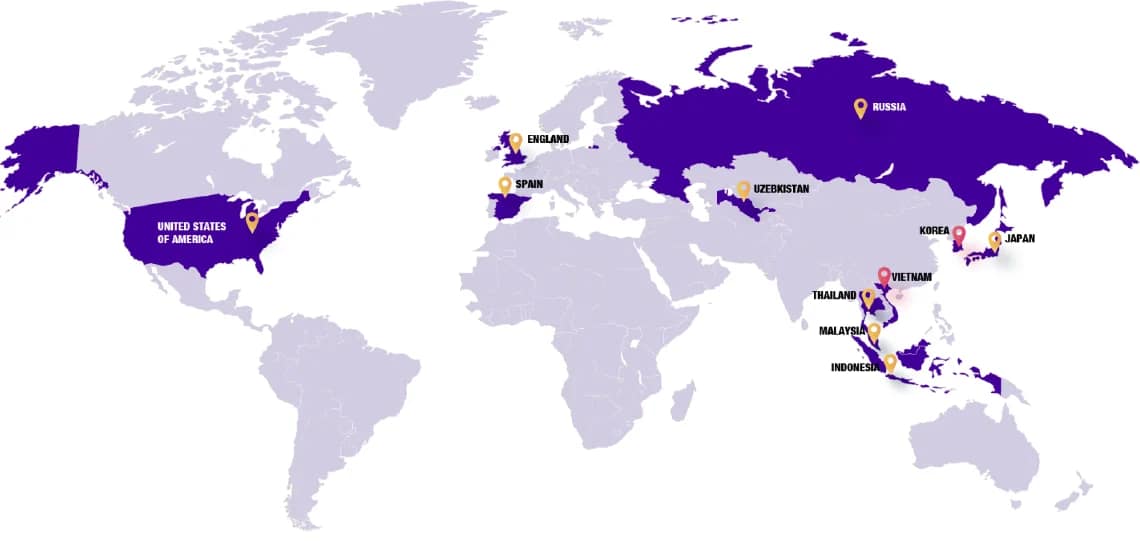

That's RK. We have exported to more than 10 countries, including the United States, Spain, Malaysia, India, Brazil, Japan, Thailand, Indonesia, and Uzbekistan.

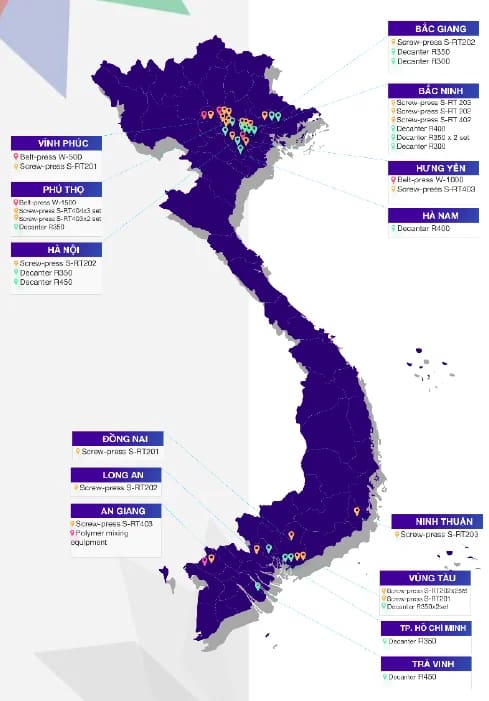

In particular, in Vietnam, our products are installed and operating in Phu Tho Water Treatment Plant, Cai Binh Water Treatment Plant, Bac Giang Water Treatment Plant, Vung Tau Water Treatment Plant, Thanh Hoa Water Treatment Plant, and many other areas.

[justified_image_grid gallery=6846]

Centrifugal dehydrator : View