Solutions in Water Environment

for People and Planet

Hello, I'm Sohee Jeon from the public relations office. This time, I will share wastewater treatment insights for petroleum refining. The petroleum industry is an energy supply industry that has not been completely replaced yet because the use of green and renewable energy is not high.

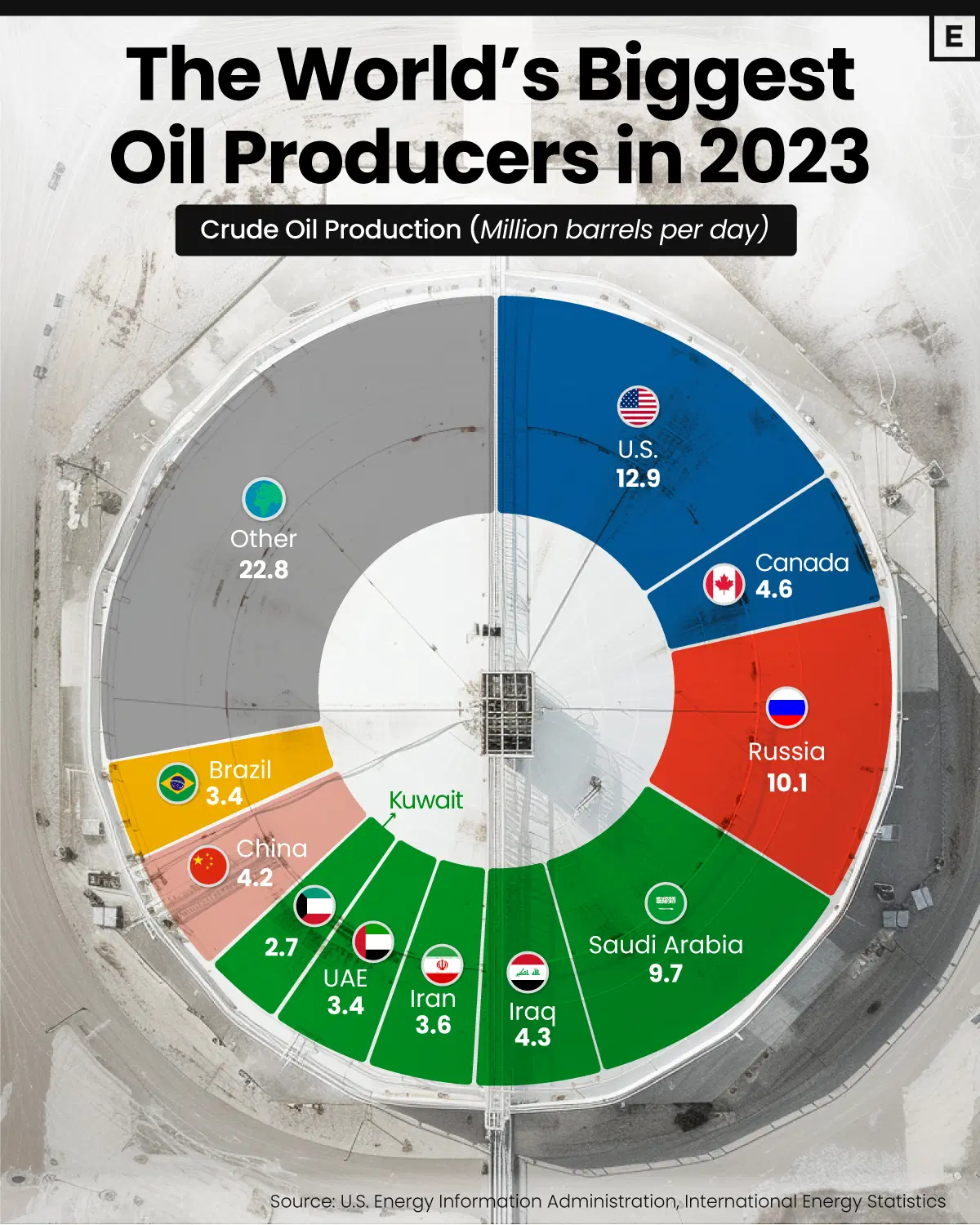

However, in the United States, shale oil has taken off with the development of shale drilling, making the country the number one oil producer and producing at record levels.

| Crude oil production in 2023 | Amount(million barrels/day) |

|---|---|

| U.S. | 12.9 |

| Russia | 10.1 |

| Saudi Arabia | 9.7 |

| Canada | 4.6 |

| Iraq | 4.3 |

| China | 4.2 |

| Iran | 3.6 |

| Brazil | 3.4 |

| UAE | 3.4 |

| Kuwait | 2.7 |

| Other | 22.8 |

The products from the fractional distillation of crude oil are gasoline, jet fuel, diesel fuel, and kerosene, which make up the majority of transportation fuels. It can also be used as a raw material for many chemical products such as plastics, pharmaceuticals, fertilizers, pesticides, and solvents.

Shale oil is primarily used as heating oil, fuel for ships, preservatives for wood for railroads, and other chemicals, and unlike crude oil, it is not used as a feedstock for chemical products.

On the other hand, the high-boiling compounds in shale oil can be used to produce intermediate oils such as kerosene, diesel, jet fuel, etc.

As such, crude oil, shale oil, and other ‘oils" are ubiquitous as energy and products in all sectors of industry and everyday life. The oil industry is still going strong and requires constant research and treatment of wastewater.

In fact, the fear of running out of oil has led the Middle East to invest in hydrogen, wind, and nuclear power as alternatives to oil.

This means that the energy industry is turning green, and countries around the world are aiming for a new paradigm shift in the environmental energy industry, with common protocols such as RE100 aiming for a low-carbon industry.

However, there are many arguments against the theory of oil depletion. Scientists and geologists have long expected oil to run out, but unexpectedly, new oil reserves and discoveries continue to grow even as new sources of oil are discovered and drilled.

Importantly, it is important to focus on alternative energy production because there is a goal and hypothesis of carbon reduction, and similarly, in wastewater treatment, we should focus on carbon reduction by recycling water and reducing the energy consumed in wastewater treatment.

There is no large company in Korea that does not invest in petroleum and refining, so the petroleum industry is a field that will always be in demand in terms of supply and demand if there is advanced plant technology, so we should be interested in advanced treatment methods for petroleum wastewater and refinery wastewater in terms of environmental technology and utilization of by-products.

Let's get down to business.

The petroleum refining industry imports crude oil and refines the imported crude oil into extracts and by-products that are processed into products for each industry and then distributed and used.

During the refining process in petroleum refineries, wastewater is primarily refinery effluent and is categorized as follows.

The classifications by nature are 1,2,3,5 (process wastewater) and 4 (cooling wastewater).

Petroleum wastewater is mainly oily ‘oil wastewater' and is generated from crude oil distillation facilities, desalting and desulfurization facilities, and cleaning and washing facilities that are unique to petroleum plants.

Oil wastewater is easy to separate because it floats on water, but for other substances, pressurized flotation/biotreatment/sand filtration/activated carbon adsorption is used.

As shown in the chart, the four treatment processes generate about 13 different substances and oils.

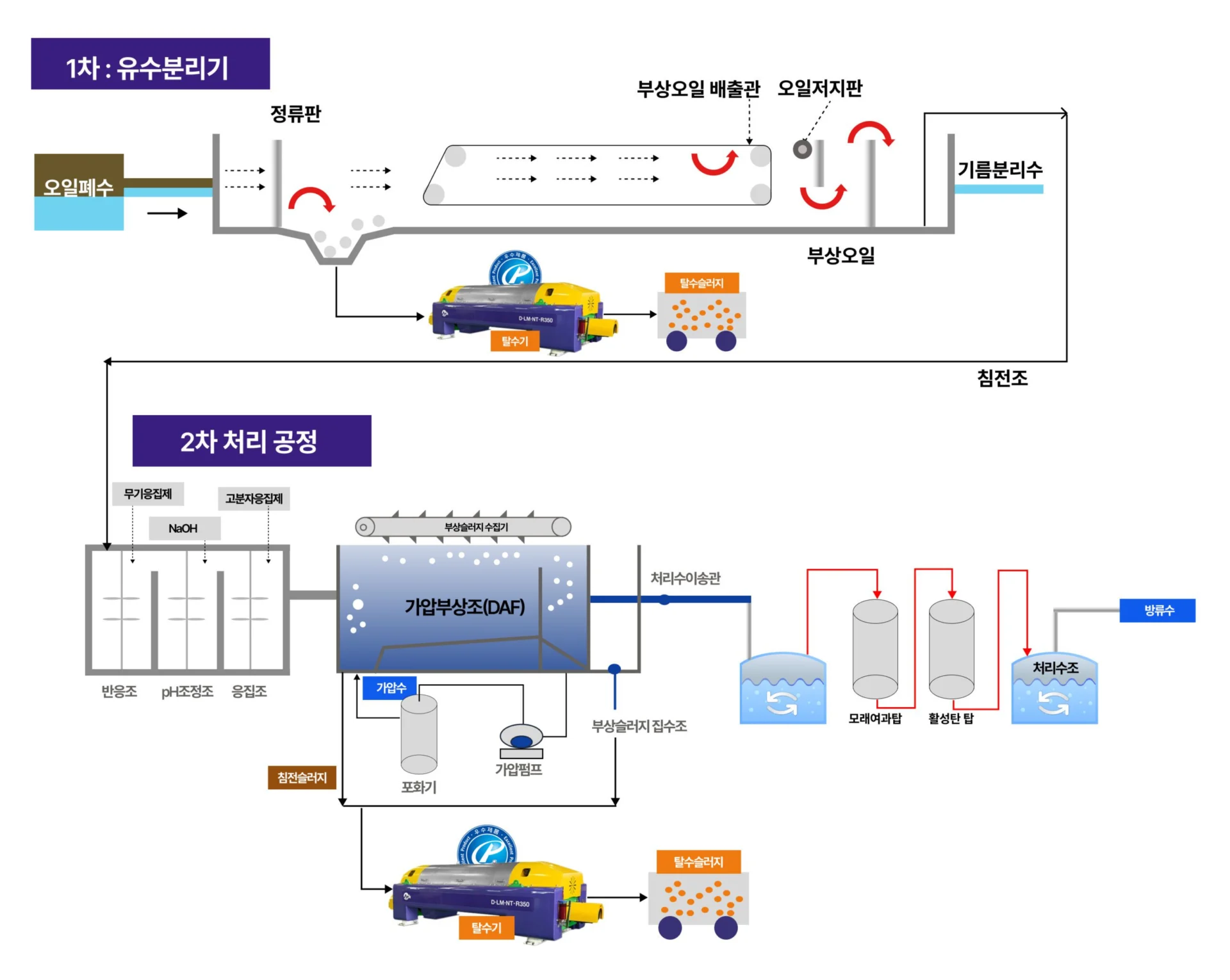

As mentioned earlier, petroleum refinery wastewater, which includes refinery wastewater and cooling wastewater, is subjected to oil-water (oil and water) separation by API, CPI, and PPI.

Oil-water separators are used in petroleum refineries where oil and palm oil are generated, junkyards, military vehicle maintenance shops, hydroelectric power plants, nuclear power plants, chemical plants, paint shops, train stations and airports. Oil-water separators for primary treatment also require sludge treatment through dewatering and have a rather complex structure with secondary treatment.

Oil water is not difficult due to the nature of oil floating on water, but the 13 or so substances mentioned above require additional treatment.

Pressurization injuries

Activated sludge

Sand filtration

Activated carbon adsorption

<As shown in Figure 2, the API oil separator can remove oil droplets down to 150 μm (microns). If there are other substances in the wastewater, such as emulsions, N-hexane, suspensions, etc.

The above API process + lateral flow pressurized flotation treatment is used for treatment facilities with large quantities, and the treated water comes out cleaner after passing through pressurized flotation tank > sand filtration tower > activated carbon tower.

CPI is suitable for low-volume facilities due to its high efficiency and compactness, and it can remove oil down to 60 μm (microns). Therefore, you can choose CPI for high-volume applications such as petroleum refineries and power plants for API and other oils, or for low-volume applications.

Process wastewater includes oils, ammonia, phenols, hydrogen sulfide, hydrocarbons, N-hexane, hydrochloric acid, sodium hydroxide, phosphates, suspended solids / Domestic wastewater includes BOD, COD, surfactants, coliforms.

Oil-water separators are used for high-volume facilities, with American Petroleum Institute (API) oil separators removing down to 150 microns (μm) and Coagulated Plate Interceptor (CPI) oil separators removing down to 60 μm.

As shown in the image above, the process consists of treating more than 13 types of wastewater through the oil-water separation stage of primary treatment and pressurized flotation in the second stage.

| Business name | Key areas | Website |

| Fields Engineering / Kari | Petrochemical and refinery plant EPC, secondary cell brine wastewater facilities | View |

| KUMKANG Engineering | Environmental Engineering | View |

| Hansung Cleantech | Petrochemical Industry Wastewater Treatment | View |

| Handok ENG | High-load petrochemical wastewater treatment system using thermophilic aerobic bacteria | View |

| VK ENG | Lava Wastewater Reuse Facility | View |

Centrifugal dehydrator for petroleum wastewater : View