ARK Decanter Centrifuge Overview

| Oil-free bearings | Application of 300, 350, 400 oil-free bearings eliminates the need for bi-weekly inspections and prevents gas damage. |

| Design | Compact, space-saving design |

| Use | Acceptable for any kind of slurry |

| Drive | Easy automatic operation and maintenance |

| Performance | Stable dewatered cake solid content maintenance |

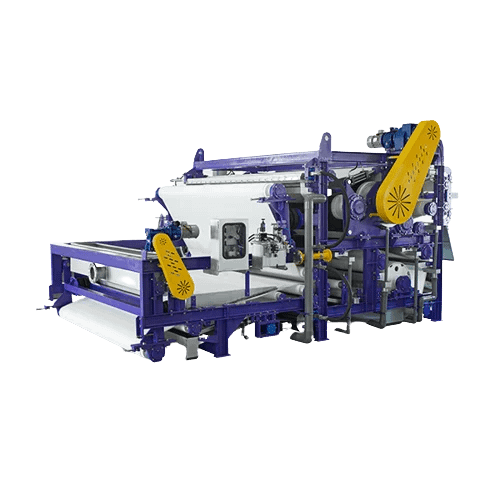

The centrifugal dehydrator consists of a bowl, screw conveyor, gearbox, drive, body, and control panel, and applies centrifugal force to the sludge entering the dehydrator by the bowl and the slowly rotating screw conveyor, so that the solids are dewatered and the separating liquid is discharged to the outside through the separating liquid outlet in the opposite direction of the solids outlet.

ARK is proud to be a leading manufacturer of offering Sludge Dewatering Machine; catering to the requirements of domestic and global customers. Decanter centrifugeis one of our main products and includes the most modern technologies.

ARK’s Decanter Centrifuges

The intelligent dolphin-shaped centrifugal dehydrator has a compact design, does not require much space and can be operated automatically. The machine parts are made of the best materials that are wear-resistant and easy to replace and maintain. ARK's centrifugal dehydrators can be said to be equipped with advanced technology and modern design.

Centrifugal dehydrators are suitable for most water and wastewater treatment systems, including food processing, pharmaceutical, water and wastewater, and physical and chemical industries.

Working Mechanism of the ARK Centrifugal Dehydrator

It consists of a bowl and a screw conveyor. They are driven by two motors that rotate at different speeds. The polymer is introduced into the dehydrator by an injection pump. The polymer is mixed with the sludge in the pipeline and accelerated to rotate at high speed inside the dehydrator. It is then separated into dewatering cake and dewatering liquor by the centrifugal force of the high-speed rotation.

Centrifugal dehydrators are installed at the last stage of the sewage treatment system. The dewatering cake discharged from the dewaterer can be reused depending on the characteristics of the sludge.

Benefits of the ARK Centrifugal Dehydrator

- ARK centrifugal dehydrators are extremely durable and precision-built.

- The machines are assembled on state-of-the-art production lines that meet ISO 9001:2015 standards.

- Simple and safe operation for easy accessibility and continuous automatic operation for easy maintenance.

- It's as smart as a dolphin. The system is completely enclosed. No sludge splashing during operation, clean and sealed system, no odor emission. The machine has an automatic cleaning system and a shutdown timer.

- The sludge moisture content and recovery rate can be easily adjusted before and during operation. The machine has a compact design that does not require much space.

- The dehydrated cake is discharged with a stable moisture content.

- Suitable for all types of wastewater with complex physicochemical properties.

Economic Benefits of Using ARK Centrifugal Dehydrators

ARK's centrifugal dewatering machines stand out in many ways. Dewatering technology using centrifugal force allows the machines to process large volumes of sludge quickly and efficiently. We have many models with different capacities, ranging from small to very large.

Sludge volume reduction of up to 901 TP3T compared to traditional dewatering methods. This is an effective solution that saves our customers money.

It also reduces labor costs and makes it easier to control moisture content and recovery.

The ARK centrifugal dewatering machine enables customers to save up to 901 TP3T in sludge disposal costs, so the initial investment in purchasing the machine is recouped after one to two years.

Quality Assurance and After-Sales Service (A/S)

Efficiency of maintenance and operation is always our top priority. ARK owns a team of specialized technicians dedicated to customer support both before and after machine acquisition. We maintain strict quality control during the design and manufacturing processes. Furthermore, we guarantee the quality standards of the wastewater treatment industry.

ARK directly designs, manufactures, and installs the sludge dewatering equipment. Our service includes operational training according to customer needs, and we help select the most suitable model with optimal capacity.

ARK Decanter Centrifuge Auxiliary Equipment

The operational system is very simple and includes only a polymer dissolution tank, a pumping system, and the polymer. Customers can either make full use of their existing polymer mixing tank or order a polymer dissolving unit from ARK.