Screw Press (Multi-Disc) Dehydrators

| KS-RT202 Specs | |

|---|---|

| Capacity | 30 to 40 kgDS/hr |

| Dimension | 2834 x 1050 x 1430 mm |

| Motors | 11 / 2.2 kW |

| Weight | 1.2 kW |

| Drawing | Drawing |

| KS-RT203 Specs | |

|---|---|

| Capacity | 45 to 60 kgDS/hr |

| Dimension | 2834 x 1400 x 1430 mm |

| Motors | 1.95 kW |

| Weight | 1500 kg |

| Drawing | Drawing |

| KS-RT204 Specs | |

|---|---|

| Capacity | 60 to 80 kgDS/hr |

| Dimension | 2834 x 1720 x 1430 mm |

| Motors | 2.35 kW |

| Weight | 2000 kg |

| Drawing | Drawing |

| KS-RT205 Specs | |

|---|---|

| Capacity | 75 to 100 kgDS/hr |

| Dimension | 2834 x 1990 x 1430 mm |

| Motors | 2.75 kW |

| Weight | 2300 kg |

| Drawing | Under preparation |

| KS-RT206 Specs | |

|---|---|

| Capacity | 90 to 120 kgDS/hr |

| Dimension | 2834 x 2330 x 1430 mm |

| Motors | 3.15 kW |

| Weight | 2600 kg |

| Drawing | Under preparation |

| KS-RT402 Specs | |

|---|---|

| Capacity | 60 to 80 kgDS/hr |

| Dimension | 4377 x 1500 x 1965 mm |

| Motors | 2.35 kW |

| Weight | 2000 kg |

| Drawing | Drawing |

| KS-RT403 Specs | |

|---|---|

| Capacity | 90 to 120 kgDS/hr |

| Dimension | 4377 x 2060 x 1965 mm |

| Motors | 3.9 kW |

| Weight | 3000 kg |

| Drawing | Drawing |

| KS-RT404 Specs | |

|---|---|

| Capacity | 120 to 160 kgDS/hr |

| Dimension | 4377 x 2300 x 1965 mm |

| Motors | 4.7 kW |

| Weight | 3800 kg |

| Drawing | Under preparation |

| KS-ST202 Specifications | |

|---|---|

| Capacity | 30 to 40 kgDS/hr |

| Dimension | 2834 x 1050 x 1540 mm |

| Motors | 1.2 kW |

| Weight | 1200 kg |

| Drawing | Under preparation |

| KS-ST203 Specifications | |

|---|---|

| Capacity | 45 to 60 kgDS/hr |

| Dimension | 2834 x 1400 x 1845 mm |

| Motors | 1.95 kW |

| Weight | 1500 kg |

| Drawing | Under preparation |

| KS-ST204 Specifications | |

|---|---|

| Capacity | 60 to 80 kgDS/hr |

| Dimension | 2834 x 1720 x 1845 mm |

| Motors | 2.35 kW |

| Weight | 2000 kg |

| Drawing | Under preparation |

| KS-ST205 Specifications | |

|---|---|

| Capacity | 75 to 100 kgDS/hr |

| Dimension | 2834 x 1990 x 1845 mm |

| Motors | 2.75 kW |

| Weight | 2300 kg |

| Drawing | Under preparation |

| KS-ST206 Specifications | |

|---|---|

| Capacity | 90 to 120 kgDS/hr |

| Dimension | 2834 x 2330 x 1845 mm |

| Motors | 3.15 kW |

| Weight | 2600 kg |

| Drawing | Under preparation |

| KS-ST402 specification | |

|---|---|

| Capacity | 60 to 80 kgDS/hr |

| Dimension | 4077 x 1528 x 2140 mm |

| Motors | 2.35 kW |

| Weight | 2000 kg |

| Drawing | Under preparation |

| KS-ST403 Specification | |

|---|---|

| Capacity | 90 to 120 kgDS/hr |

| Dimension | 4277 x 2060 x 2186 mm |

| Motors | 3.9 kW |

| Weight | 3000 kg |

| Drawing | Under preparation |

| KS-ST404 specifications | |

|---|---|

| Capacity | 120 to 160 kgDS/hr |

| Dimension | 4277 x 2300 x 2186 mm |

| Motors | 4.7 kW |

| Weight | 3800 kg |

| Drawing | Under preparation |

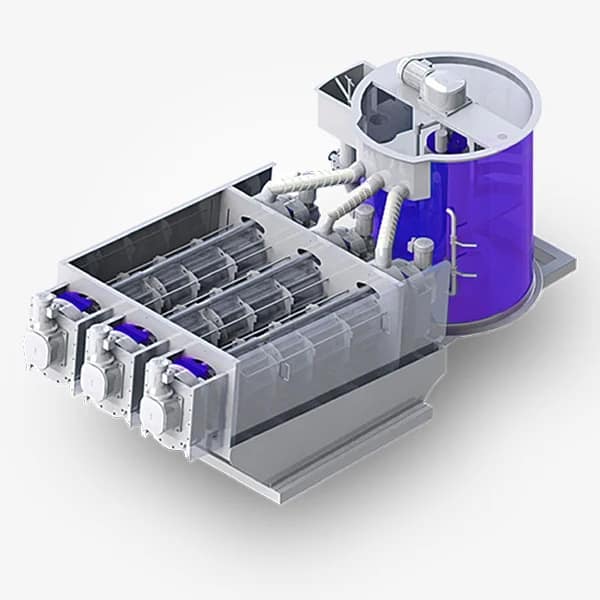

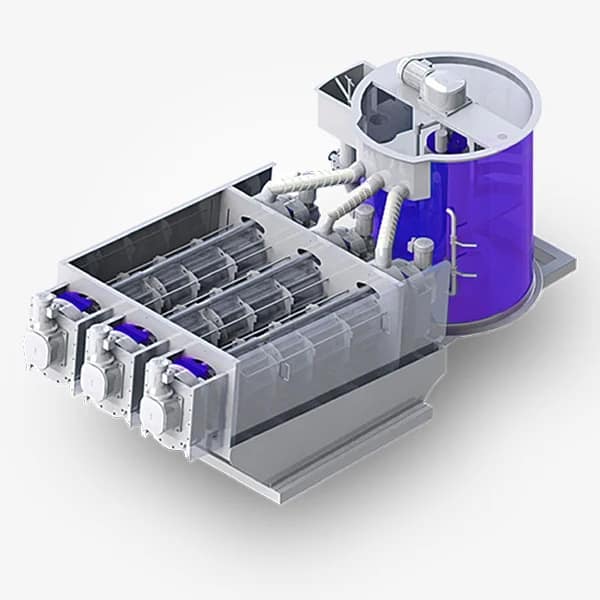

This is a 3D image of a screw press developed by engineers in ARK's R&D department. You can clearly see the details of each part: motor, screw shaft, fixed disk, movable disk, etc.

Optimal requirements for 3D viewing: PC (i5 or later), mobile (Android 7.0 or later or IOS 14.0 or later)

Screw press (multi-disc dehydrator)

| Design | Compact, space-saving design |

| Use | Suitable for sewage, wastewater sludge |

| Features | Low power, low noise, low vibration |

| Structure | Sealed, easy-to-maintain construction |

The sludge entering the dehydrator is mixed and agglomerated with polymer, and after primary concentration in the concentrator, it is pressed and dehydrated in the dehydration screw consisting of a flow ring and a fixed ring, and discharged as dehydration cake and dehydration filtrate.

ARK Product Strengths

About the ARK Screw Press (Multi-Disc Dehydrator)

Screw press (multi-disc dehydrator) is a popular sludge dewatering machine in the market due to its high applicability in many factories, industrial zones and various industries, especially its ability to reduce construction costs. The screw press (multi-disc dewatering machine) is used in the last stage of the water treatment process, and its compact design minimizes the footprint and is durable.

Mechanism of the ARK screw press (multi-disc dehydrator)

- KS-ST Type

It is suitable for low concentration sludge with sludge concentration less than 1%. The sludge entering the thickener is concentrated to twice the incoming concentration and transported to the dewatering screw for pressing and dehydration. There is a filtrate discharge device inside the thickener to separate the incoming sludge into concentrated filtrate and concentrated sludge.

- KS-RT Type

It is a flocculation tank type product and is suitable for high concentration sludge with sludge concentration of 1% and above. The sludge entering the flocculation tank is flocculated with polymer and transported to the dewatering screw for pressing and dehydration.

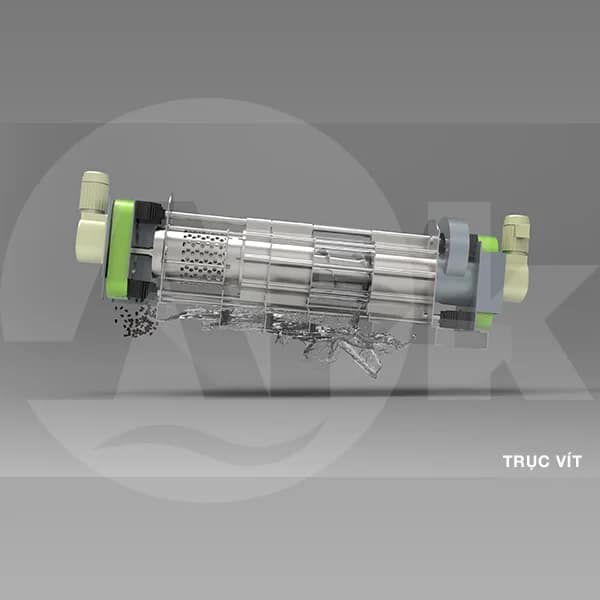

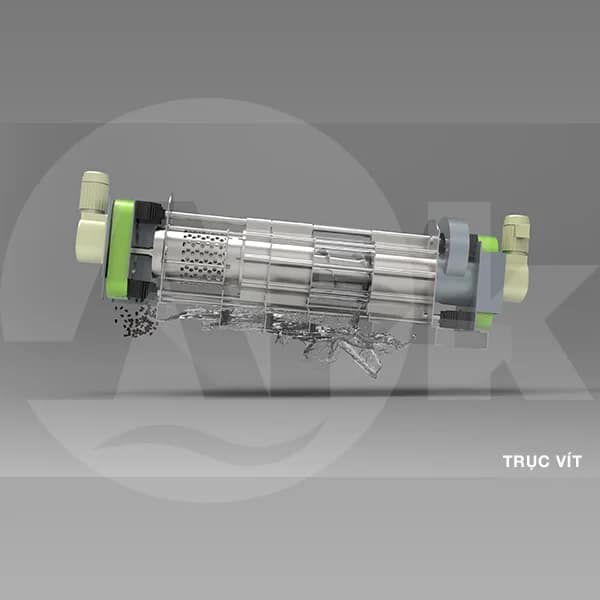

- Dewatering Screw Mechanism

The dewatering screw consists of a flow ring, a fixed ring, and a washer, and the sludge entering the screw is pressed and dewatered by discharging the filtrate between the flow ring and the fixed ring, and the gap between the rings is formed by the washer.

During operation, the floating ring flows from side to side at all times to ensure that the gap between the floating ring and the fixed ring is not occluded. The sludge is discharged in the form of a dewatering cake between the backing plates as the water content decreases towards the rear end of the screw.

- Applicability

Screw presses (multi-disc dewatering machines) are suitable for many different types of sludge, including.

- Sewage treatment plant, wastewater treatment plant sludge

- Food processing: seafood, livestock, and domestic water treatment.

- Processing vegetable oils, such as pressing peanut oil, extracting coconut oil, extracting coconut milk...,

- Textile dyeing, paper production, plating, plastic production, cosmetics, ceramic tiles, mining ...,

ARK screw presses have more application possibilities. They are suitable for a wider range of applications than belt presses and filter presses.

Benefits of the ARK Screw Press (Multi-Disk Dehydrator)

Economic benefits of using a screw press (multi-disc dehydrator)

In many ways, screw presses (multidiscipline dehydrators) are superior.

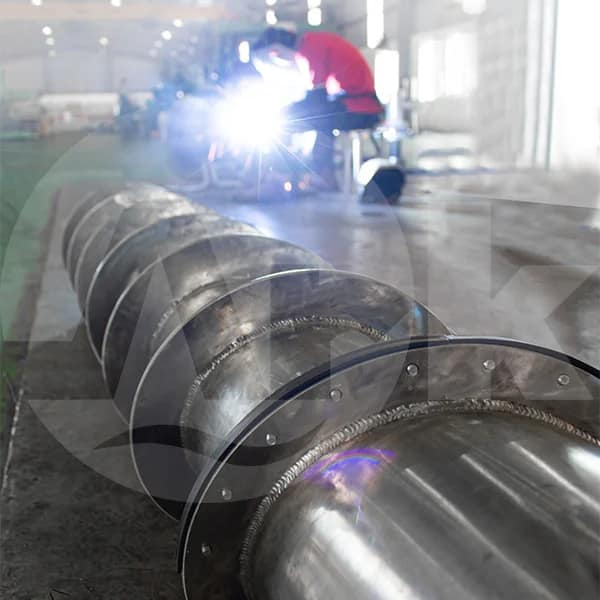

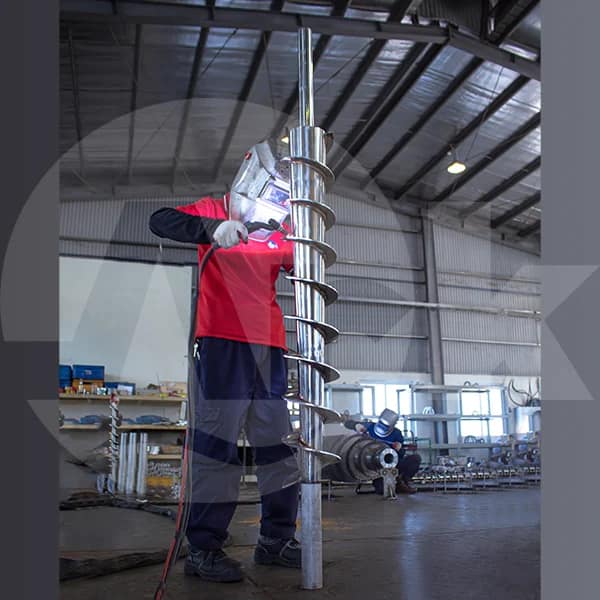

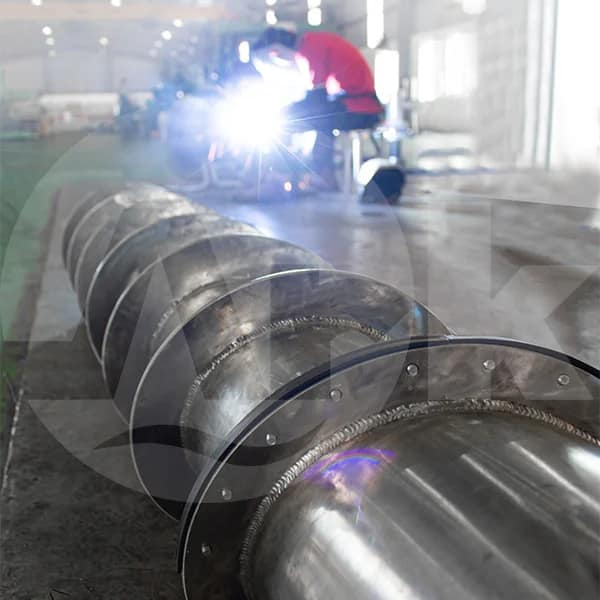

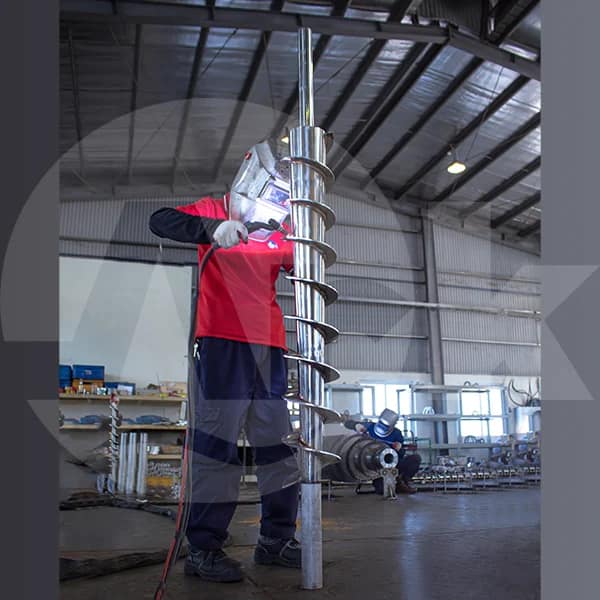

They are low-speed, wear-resistant and made of stainless steel. The machines are self-contained, easy to maintain and we try to supply them at the lowest cost. We also have different shapes of models suitable for sludge of different consistency.

The low-power, low-noise design makes it highly effective for individual replacement and retrofitting of dewatering screws.

Each dewatering screw can be removed for maintenance, so you don't have to worry about downtime for maintenance.

Quality Assurance and After-Sales Service (A/S)

Efficiency in maintenance is always our top priority. ARK owns a team of professional technicians who are dedicated to supporting customers before and after the purchase of the machine, and we thoroughly support our customers from the purchase and after-sales stage.

ARK has the core technology. ARK provides consulting services to help customers choose the most suitable model, and we are committed to on-site installation, commissioning, and driver training.

| KS-RT202 | View |

|

| KS-RT203 | View |

|

| KS-RT204 | View |

|

| KS-RT402 | View |

|

| KS-RT403 | View |

There are two types of dehydrators: thickener-attached dehydrators (ST type) for low-concentration sludge, and flocculation tank dehydrators (RT type) for high-concentration sludge. There are models of each type in various capacities.

The unique design of the dehydration screw is tapered to prevent occlusion of the ring gap by the movement of the flow ring. In addition, the rear end of the screw is perforated to minimize mechanical losses due to increased pressure and improve the moisture content of the dehydrated cake.

The ST type is a thickener-attached dewatering machine suitable for low concentration sludge (less than 11 TP3T), while the RT type is a flocculation tank dewatering machine suitable for high concentration sludge (more than 11 TP3T).

ARK holds plenty of stock for spare parts in our factories in Vietnam and Korea. The spare parts are delivered to your sites no sooner than we receive your request. In case of issues of mechanical malfunctions, our skillful technical team rushes to the customer's site in Asian countries for immediate maintenance and repair. In addition, the team is pleased to visit your plants at regular intervals for checking the machines.

We have a professional sales team to help you choose the right dehydrator model and select an economical dehydrator through on-site visits and consultations.