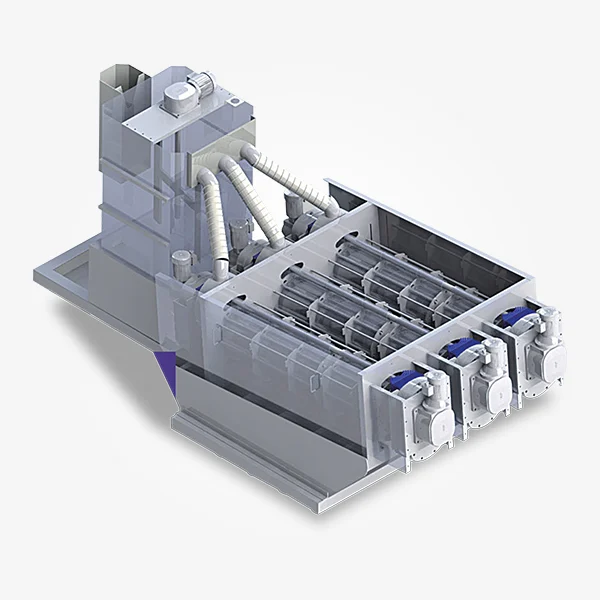

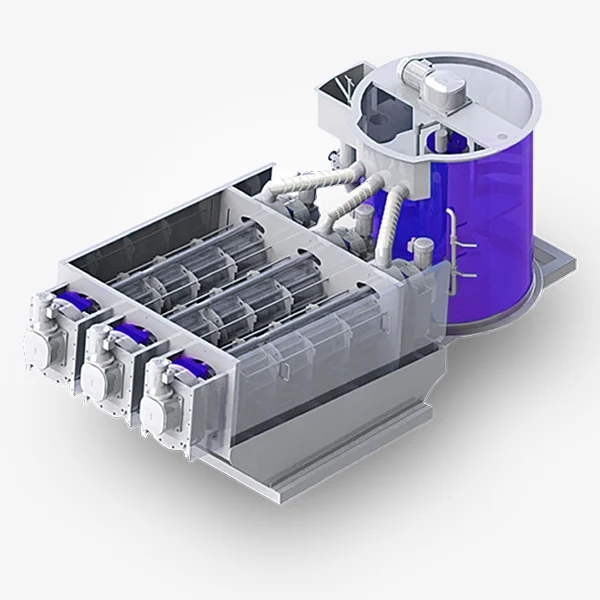

Screw-press

(multi-disk screw-press)

(multi-disk screw-press)

| KS-RT202 Specs | |

|---|---|

| Capacity | 30 – 40 kgDS/hr |

| Dimension | 2834 x 1050 x 1430 mm |

| Motors | 11 + 2.2 kW |

| Weight | 1200 kg |

| Drawing (for reference) | Drawing (for reference) |

| KS-RT203 Specs | |

|---|---|

| Capacity | 45 – 60 kgDS/hr |

| Dimension | 2834 x 1400 x 1430 mm |

| Motors | 1.95 kW |

| Weight | 1500 kg |

| Drawing (for reference) | Drawing (for reference) |

| KS-RT204 Specs | |

|---|---|

| Capacity | 60 – 80 kgDS/hr |

| Dimension | 2834 x 1720 x 1430 mm |

| Motors | 2.35 kW |

| Weight | 2000 kg |

| Drawing (for reference) | Drawing (for reference) |

| KS-RT205 Specs | |

|---|---|

| Capacity | 75 – 100 kgDS/hr |

| Dimension | 2834 x 1990 x 1430 mm |

| Motors | 2.75 kW |

| Weight | 2300 kg |

| Drawing (for reference) | Under preparation |

| KS-RT206 Specs | |

|---|---|

| Capacity | 90 – 120 kgDS/hr |

| Dimension | 2834 x 2330 x 1430 mm |

| Motors | 3.15 kW |

| Weight | 2600 kg |

| Drawing (for reference) | Under preparation |

| KS-RT402 Specs | |

|---|---|

| Capacity | 60 – 80 kgDS/hr |

| Dimension | 4377 x 1500 x 1965 mm |

| Motors | 2.35 kW |

| Weight | 2000 kg |

| Drawing (for reference) | Drawing (for reference) |

| KS-RT403 Specs | |

|---|---|

| Capacity | 90 – 120 kgDS/hr |

| Dimension | 4377 x 2060 x 1965 mm |

| Motors | 3.9 kW |

| Weight | 3000 kg |

| Drawing (for reference) | Drawing (for reference) |

| KS-RT404 Specs | |

|---|---|

| Capacity | 120 – 160 kgDS/hr |

| Dimension | 4377 x 2300 x 1965 mm |

| Motors | 4.7 kW |

| Weight | 3800 kg |

| Drawing (for reference) | Under preparation |

| KS-ST202 Specs | |

|---|---|

| Capacity | 30 – 40 kgDS/hr |

| Dimension | 2834 x 1050 x 1540 mm |

| Motors | 1.2 kW |

| Weight | 1200 kg |

| Drawing (for reference) | Under preparation |

| KS-ST203 Specs | |

|---|---|

| Capacity | 45 – 60 kgDS/hr |

| Dimension | 2834 x 1400 x 1845 mm |

| Motors | 1.95 kW |

| Weight | 1500 kg |

| Drawing (for reference) | Under preparation |

| KS-ST204 Specs | |

|---|---|

| Capacity | 60 – 80 kgDS/hr |

| Dimension | 2834 x 1720 x 1845 mm |

| Motors | 2.35 kW |

| Weight | 2000 kg |

| Drawing (for reference) | Under preparation |

| KS-ST205 Specs | |

|---|---|

| Capacity | 75 – 100 kgDS/hr |

| Dimension | 2834 x 1990 x 1845 mm |

| Motors | 2.75 kW |

| Weight | 2300 kg |

| Drawing (for reference) | Under preparation |

| KS-ST206 Specs | |

|---|---|

| Capacity | 90 – 120 kgDS/hr |

| Dimension | 2834 x 2330 x 1845 mm |

| Motors | 3.15 kW |

| Weight | 2600 kg |

| Drawing (for reference) | Under preparation |

| KS-ST402 Specs | |

|---|---|

| Capacity | 60 – 80 kgDS/hr |

| Dimension | 4077 x 1528 x 2140 mm |

| Motors | 2.35 kW |

| Weight | 2000 kg |

| Drawing (for reference) | Under preparation |

| KS-ST403 Specs | |

|---|---|

| Capacity | 90 – 120 kgDS/hr |

| Dimension | 4277 x 2060 x 2186 mm |

| Motors | 3.9 kW |

| Weight | 3000 kg |

| Drawing (for reference) | Under preparation |

| KS-ST404 Specs | |

|---|---|

| Capacity | 120 – 160 kgDS/hr |

| Dimension | 4277 x 2300 x 2186 mm |

| Motors | 4.7 kW |

| Weight | 3800 kg |

| Drawing (for reference) | Under preparation |

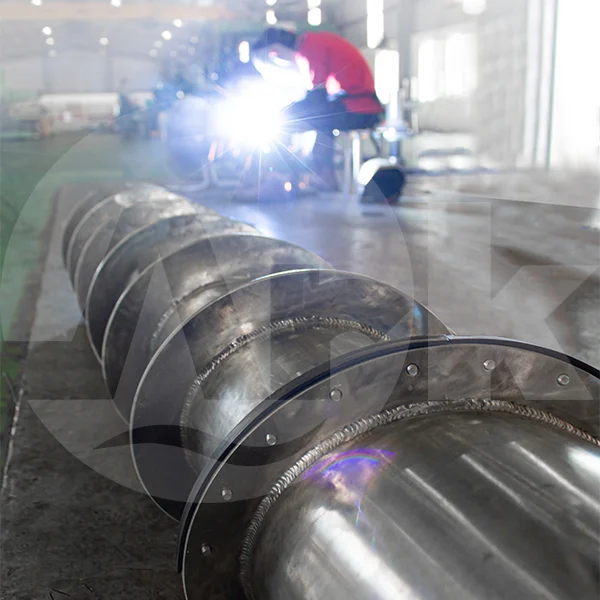

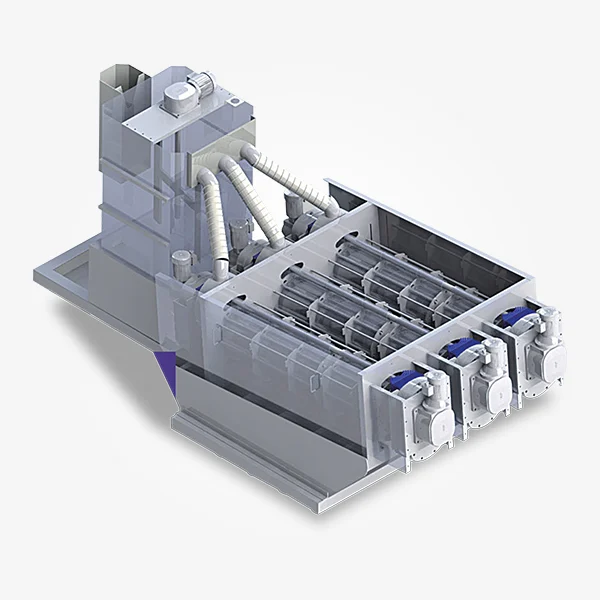

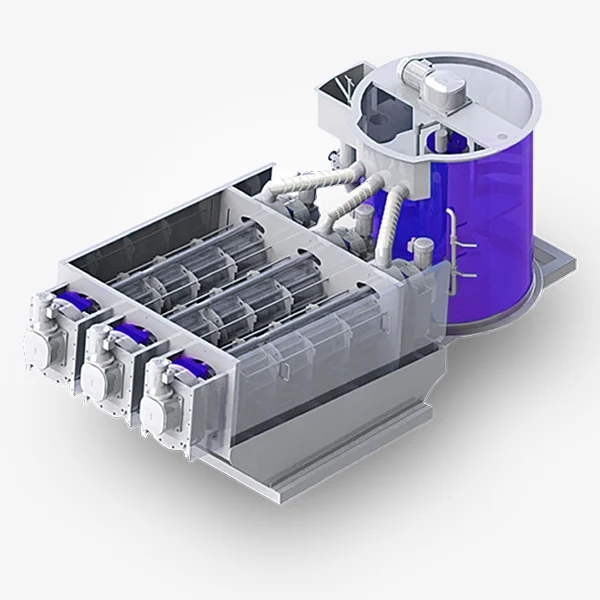

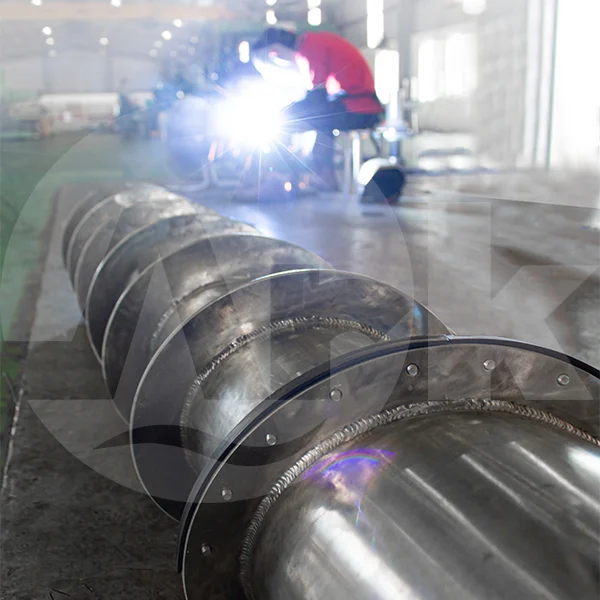

This is a 3D image of a screw press developed by engineers in ARK's R&D department. You can clearly see the details of each part: motor, screw shaft, fixed disk, movable disk, etc.

Optimal requirements for 3D viewing: PC (i5 or later), mobile (Android 7.0 or later or IOS 14.0 or later)

ARK Multi-disk Screw-press Overview

| Capacity | Up to 160 kgDS/hr |

| Fed slurry concentration | 0.6 – 3.0 % |

| Acceptable slurry type | Flocculated slurries |

| System | Screw-press with self-cleaning mechanism, equipped with a sludge flocculation/thickening tank |

💧Strong points of ARK’s screw-press system

⚙️ Operational Principles for ARK’s multi-disk screw-press system

ARK’s screw press system has a unique flocculation/sludge thickening tank for the pretreatment of sludge dewatering.

Depending on the slurry concentration of the factories/treatment plants, either the KS-ST type or the KS-RT type is chosen from the lineups.

💧KS-ST type

💧KS-RT type

⚙️Sludge dewatering in the multi-disk screw-press

🏭 Reasons that you need to install the sludge dewatering system at your factories/treatment plants

ARK’s screw-presses enable remarkable cost reduction in your factories and treatment plants.

Due to the unique mechanism, the machines are able to receive low-strength slurry for sludge dewatering. In case the capacity of the existing sludge thickener is limited at the factories/treatment plants, this unique feature is particularly of interest. Our lineups having a wide range of capacity must cover any factories and treatment plants in size of production.

Furthermore, the labor cost for the sludge treatment at the factories/plant can also be correspondingly reduced. This is because the machines can receive a high volume of the slurry per unit of time.

In general, the expense for sludge treatment, including sludge disposal, can be reduced to as low as 10% of that outsourced in a slurry form. This means that the investment cost of the sludge dewatering machine may be recovered within 1-2 years.

🤝Customer-support services

| Machine type | View on browser | Download Electronic Files |

|---|---|---|

| KS-RT202 | View |

|

| KS-RT203 | View |

|

| KS-RT204 | View |

|

| KS-RT402 | View |

|

| KS-RT403 | View |

The KS-ST type is able to receive low-strength slurry, even a concentration below 1%. The KS-RT type is ideal to perform sludge dewatering for the thickened slurry.

The taper of the screw creates a consistent development of internal pressure along the screw length, where the water fraction of the flocculated slurry is mechanistically spilled out from the gaps of the ring-shaped disks surrounding the screw. The combination of the moving ring-shaped disks and the fixed ring-shaped disks creates a scouring effect to minimize clogging.

The KS-ST type is a sludge dewatering system treating relatively low-strength slurry (below 1%). The system is equipped with a mesh filter to concentrate particles in the flocculation/sludge thickening tank. The KS-RT type is not equipped with the mesh filter and is suitable for treating already-thickened slurry.

ARK holds plenty of stock for spare parts in our factories in Vietnam and Korea. The spare parts are delivered to your sites no sooner than we receive your request. In case of issues of mechanical malfunctions, our skillful technical team rushes to the customer's site in Asian countries for immediate maintenance and repair. In addition, the team is pleased to visit your plants at regular intervals for checking the machines.

We are pleased to suggest the best-fit machine type and capacity, depending on the sludge production at your factories/treatment plants.

Brochure about ARK’s products

(in Korean language)

ARK News

(machine-translated)

-

안녕하십니까, (주)에이알케이입니다. 유난히 뜨거웠던 열정을 뒤로하고, 2026년 병오년(丙午年) 새해가 밝았습니다. ‘적마(赤馬)’의 해를 맞아, 쉼 없이 대지를 달리는 말의 기운처럼 여러분의 모든 걸음이 힘찬 성취로 이어지기를 진심으로 기원합니다. 지난 2025년을 돌이켜보면, 전 세계 물산업은 그 어느 때보다 역동적이고 긴박한 변화의 중심에 있었습니다. 국내에서는 물 산업의 디지털 전환과 스마트 물관리 체계 구축이 주요 화두로 떠올랐고, 국외로는 베트남과 […]January 1, 2026

-

Vietnam has been dubbed the ‘new dragon of Asia" due to its spectacular economic growth. But beneath the glittering growth are serious growing pains. Endless waste, polluted nature, and graying skies. The Vietnamese government has recognized the seriousness of the problem and has drawn the sword of the law, but with great change comes great opportunity. Right now, Vietnam's environmental problems are paradoxically [...].October 28, 2025

-

Vietnam Water Market Insights Source: Water & Sewerage / Overseas Construction Association Hyo Eun Kim Vietnam's spectacular economic growth is no secret. However, there is another reality behind this spectacular growth that we need to pay attention to. That is the issue of water infrastructure. Despite having abundant water resources, dilapidated water facilities that cannot keep up with the pace of rapid urbanization and industrialization are a challenge that Vietnam must address, and at the same time, a barrier to new business [...]October 30, 2025

-

My name is Seulgi Kim, Marketing Manager of ARK company. ARK is participating in the 3-day VIETNAM WATER WEEK exhibition. Vietnam Water Week 2025 is an international exhibition in the field of water supply, sewage, water purification, wastewater treatment and environmental sanitation, and is a well-established environmental exhibition in Vietnam. We will be showcasing our next-generation decanter centrifuge, which has been continuously improving its performance through ongoing research and development (R&D) projects to ensure outstanding efficiency, and will be attracting much attention [...]August 6, 2025

-

ARK Participation in Indonesia Water Treatment Expo! Hello, this is Seulgi Kim, ARK Korea Marketing Manager. ARK is participating in a water treatment fair in Indonesia. We would like to meet and greet with many representatives and companies related to sewage and wastewater treatment in Indonesia and explain our products. We are a product that has received the best rating as a ‘procurement superior product‘ certified by the Korean government, which is designed to meet the standards of advanced urban water treatment in Korea. We have entered the Indonesian water industry and [...]August 6, 2025

-

Review of NVEX 2025, Valuable time to meet decanter centrifuge and screw press buyers Our booth, which was visited by many people, was closely watched not only by buyers but also by representatives of related organizations such as the water cluster and the Korea Environment Agency. As a company belonging to the water industry cluster, we also participated in the exhibition with pride. Our booth, which was visited by many people, was observed not only by buyers, but also by representatives of related organizations such as the water cluster and the Korea Environment Agency. Let me introduce the companies whose booths attracted attention among the various companies. CJK (CJK) Website [...]June 17, 2025

-

Meet the future of innovative decanter centrifuge technology We invite you to the exhibition! Dear water industry stakeholders, RK, a leading innovator in the water industry, invites you to a special exhibition at COEX L-13 from Wednesday, June 11th to Friday, June 13th. At this exhibition, we will be exhibiting our highly efficient decanter centrifuges that incorporate our unique technology. Our decanter centrifuges, which will contribute to solving environmental problems and increasing resource efficiency, are already used in many industrial [...]August 10, 2025

-

https://www.loud.kr/contest/view/170083 👆👆👆 View the crowdsourcing contest (designer account required)👆👆👆 👆👆👆 Greetings - Why are you starting a project? Hello, we are a dehydrator development company. For those who work in the water industry, dehydrator is a common term, but for those who don't, it may be unfamiliar. We are a Korean company with a factory in Vietnam that develops various types of dehydrators, which are devices for dehydrating sewage and wastewater in the water industry. Currently, as a carbon reduction project, we are combining decanter centrifuges with FRP in addition to the existing stainless steel [...].August 10, 2025

-

Hello, dear RK family! 🎊 On the occasion of the Chinese New Year 2025, we would like to extend our heartfelt greetings to you. We would like to express our deepest gratitude to everyone who has been with us in the past year. Just like the dehydrator we developed for water treatment, we hope this year will be a year where the unnecessary things in your life are cleanly dehydrated and only the pure and valuable things remain. 💧✨ Chinese New Year is a holiday for sharing precious time with family and friends, and with the busy [...]...August 10, 2025

-

Dear Customers, Greetings from all of us at ARK on the occasion of the year 2025. The year 2024 was a year in which the Korean water industry made a significant leap forward. Overseas exports through the Korea Environment Agency's water cluster reached KRW 109.3 billion, a remarkable achievement, and the overall growth rate of the industry remained stable at 2.91 TP3T. In particular, as long as digital transformation accelerated across the water industry and eco-friendly solutions were actively developed to respond to climate change, [...]August 10, 2025

-

Hello, I'm Sohee Jeon, a public relations manager at ARK, and I'd like to share my experience of VIETWATER2024, which took place last week from the 6th to the 8th. Held at the Saigon Exhibition & Convention Center (SECC), it was a meaningful event that made us realize how deep and important the water industry is in Southeast Asia. Water is a food and energy resource that can sustain irreplaceable life energy called ‘WATERGY‘ in the future. On the other hand, after extreme weather events, we are affected by heavy rainfall flooding in an unpredictable short time. In this [...]August 10, 2025

-

Hello, this is RK. We are participating in the historic VIETWATER event. We will participate in VIETWATER 2024, Vietnam's largest water industry exhibition. VIETWATER is Vietnam's largest water industry exhibition, showcasing the latest solutions and products in water management, water treatment, and environmental technology. The annual event gathers companies and professionals from around the world to discuss sustainable water management, water recycling, wastewater treatment, and [...]August 10, 2025

Categories

Brochure about ARK’s products

(in Korean language)