What is a decanter centrifuge?

This is an environmental column provided by ARK, a series of contents that reviews various terms and concepts that are easy to forget even for those in charge of environmental facilities and provides basic knowledge of environmental engineering to the general public.

As the domestic pioneer of centrifugal dehydrators and the only company in Vietnam that develops its own centrifugal dehydrators, we would like to clarify some confusing terms in this first installment.

Let's get started, shall we?

Centrifugation, centrifugal dehydration, centrifugal concentration, what the heck?

Is a centrifuge a top-level concept, and if so, how are dehydrators and concentrators categorized?

First, we need to unpack and understand the word centrifugal.

In physics terms, centrifugal force is the force in a rotating system that is equal in magnitude and opposite in direction to the ‘real" centripetal force. However, the two are not an action-reaction relationship. The easiest way to understand this is to think of a washing machine, which uses centrifugal force to dehydrate water by rotational motion.

Separate solid-liquid / liquid-liquid suspensions suspended solids. 1 and 2 are equivalent.

Solid-liquid

Liquid-liquid

③ Solid-Gas

④ Liquid-Gas

⑤ Gas-Gas

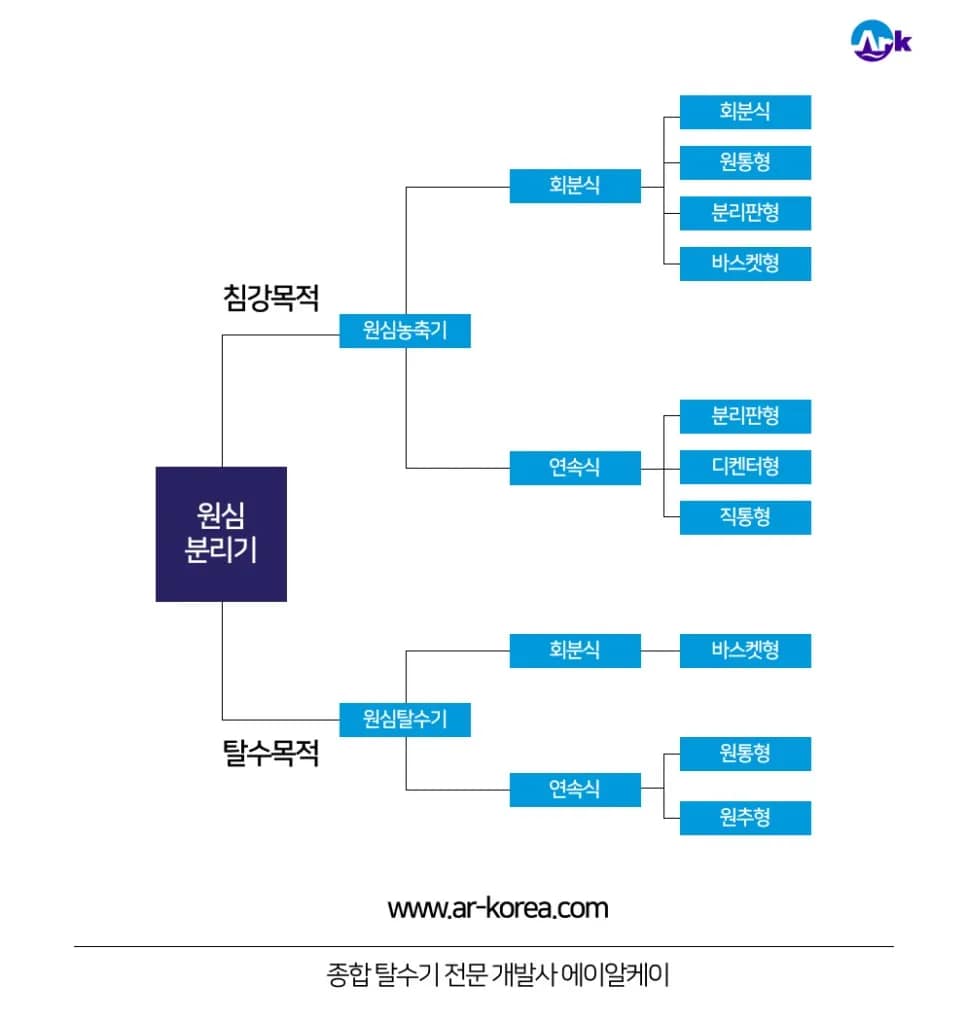

Centrifuge is the most comprehensive concept and is divided into concentrator for settling purpose and dehydrator for dehydration purpose according to the purpose, and is divided into rotary and continuous type according to the operating mechanism, and is further classified into separator plate type, basket type, direct through type, and decanter type. ARK's centrifugal dehydrator is a decanter type and is named Decanter Centrifuge in English.

The most common types of centrifuges today are the ‘decanter" type, which can be used in large plants and large enterprises and is easier to discharge sediment, and the straight-through type, which was developed for concentrators.

What is a decanter? A tool for filtering sediment that has a narrow, elongated mouth and a wide interior.

Dewatering and concentrating machines used in various industries can be categorized into chartered belt presses, filter presses, and next-generation Screw-press, And then you have the most modern centrifuges. In the industry, wherever you have sludge on site, you're going to have to dewater it, and it's going to be expensive, so you're going to have to make a choice between doing it the traditional way and doing it with labor, or you're going to do it more efficiently and justify the initial investment.

However, in recent years, especially in foreign countries, centrifugal dehydrators have been preferred due to their high efficiency. Even if the investment cost is higher than other dehydrators, centrifugal dehydrators are being replaced. This is due to its high efficiency and wide range of applications. There is also a trend toward fewer water treatment workers and safety concerns. This is because the sludge treatment process requires a lot of manpower, and if there are many post-treatment processes, there is also a lot of labor waste.

A good centrifugal dehydrator or separator is one that has a high centrifugal effectiveness, G. Of course, it has to be mechanically sound, but a good centrifugal effect should be able to concentrate and separate well.

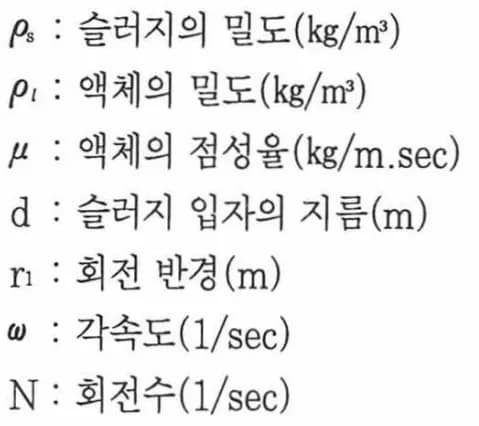

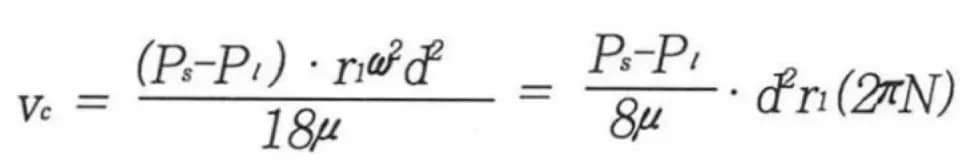

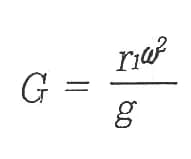

Here is a formula for Stokes' sedimentation theory that appears on the Water Environment Technician exam.

What is Centrifugal Effect G?

Where Vc is the terminal settling velocity (single particle of sludge) and G is the ratio of the artificial centrifugal acceleration due to rotational motion to the acceleration of gravity (g).

Vc (the settling velocity in a centrifugal field) is redefined as Vg (the settling velocity in a gravitational field), which means that even particles that cannot settle in gravity can be separated quickly by maintaining G times the gravitational field.

Centrifuges have a very broad spectrum of possible applications compared to other dehydrators. Roughly, the applications are categorized as follows. Dewatering, to remove water, and concentration, to concentrate and remove specific substances.

Let's take a look at the different applications of centrifugal dehydrators in different industries.

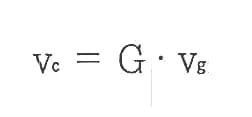

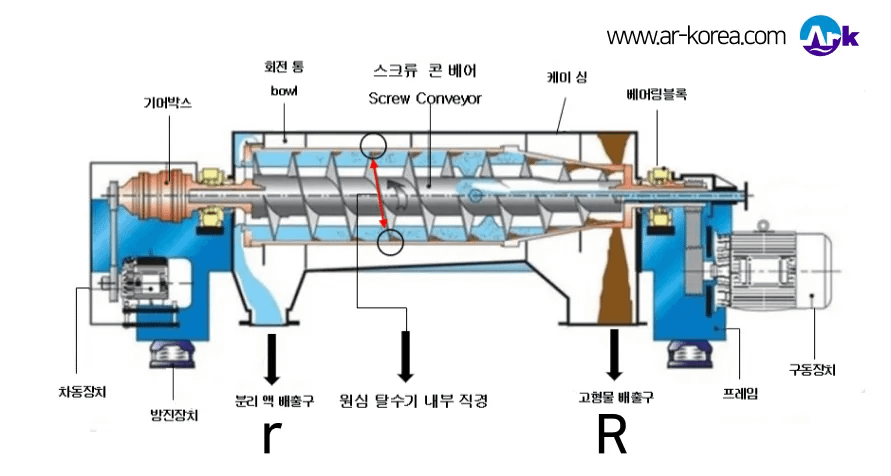

Centrifuges typically consist of a rotating bowl, screw conveyor, drive, and gearbox (transmission).

It is driven by a drive that rotates the rotary barrel and a differential drive that regulates the speed of the screw conveyor. The rotating barrel rotates at high speed and the screw conveyor inside the barrel rotates at a slightly slower speed, i.e. it is driven by motors that rotate at different speeds.

In this case, the rotation of the screw conveyor is regulated by a differential drive.

Rotating barrel (outer cylinder) - Bowl

: High-speed rotating parts that require ultra-precise machining in a variety of robust materials.

Screw

Wear-resistant materials withstand rotation, water and sludge. ARK uses Tungsten Carbide, carbide tips.

Reduction Gears (Submotors)

The ARK is a universal reducer that is easy to maintain as a reduction gear device to adjust the rotation speed of the centrifugal dehydrator.

Solids outlet

Dewatered solids are a major contributor to environmental pollution and require a material that is resistant to abrasion. ARK utilizes carbide in removable ceramic for easy maintenance.

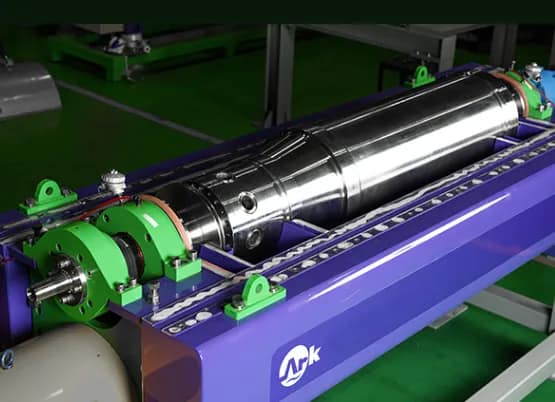

The structure and working mechanism of the centrifugal dehydrator is described based on the ARK D-LM-NT model of the decanter type. The capacity of the dehydrator is presented according to the model specifications, and the inner diameter of the bowl (outer cylinder/rotating cylinder) and the outer diameter of the screw are proportional, while the developer's models are mostly expressed in diameter.

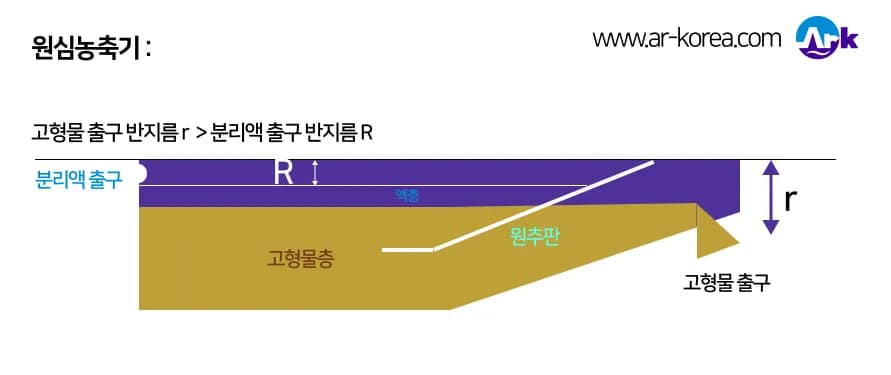

The solids outlet (no. 10) has the wrong radius value compared to the separation liquid outlet (no. 8) and the solids settle on the dry beach before being discharged. This promotes dehydration.

: (#10) Solids outlet radius is larger than (#8) Separate outlet radius, no dry beach.

At this time, a cone plate is attached to prevent the separating liquid from flowing out with the solids, and since the separating liquid outlet radius is smaller than the solids outlet radius, the solids near the solids outlet are pressed by liquid pressure, so the solids are conveyed by a screw conveyor and liquid pressure.

Centrifugal dehydrators are designed to have dry beaches because it is difficult to discharge solids without sufficient water removal, and centrifugal concentrators are designed to quickly discharge centrifuged solids.

This is why centrifugal dehydrators are often run without chemical injection, as chemical injection is necessary to turn the sludge particles into a solid floc, and centrifugal concentrators have no justification for doing so.

For more information : https://www.scienceall.com/%EC%9B%90%EC%8B%AC%EB%B6%84%EB%A6%AC%EA%B8%B0centrifuge/